In 2026, the world of Surgical Instruments is evolving rapidly. A surgeon’s success relies heavily on the tools they use. Quality surgical instruments can make a significant difference in patient outcomes. Therefore, choosing the right instruments is crucial.

When considering surgical instruments, several aspects deserve attention. Material quality, design, and precision play vital roles. New technologies bring innovations that improve functionality and safety. However, not all new instruments live up to these promises. It raises questions about their reliability and effectiveness.

Surgeons often face challenges in balancing quality with affordability. Investing in the best tools is essential, yet budget constraints are real. Some instruments may look advanced but fail in practical use. As we explore the best surgical instruments of 2026, it is vital to recognize both advancements and shortcomings in this field.

The surgical instruments landscape is evolving rapidly in 2026. Surgeons now prioritize precision and efficiency. Innovative designs are reshaping the traditional tools, making surgeries more precise. New materials, like advanced composites, enhance durability and reduce weight significantly. This evolution affects how surgeries are performed.

When choosing instruments, don’t overlook ergonomics. A comfortable grip is vital during long procedures. It can help minimize fatigue. Look for tools that offer a balanced feel in hand. This balance can make a big difference.

Remember to reflect on maintenance needs. Instruments require regular upkeep to ensure longevity. Neglecting care can lead to performance issues. Investing time in proper storage and cleaning practices is essential. A well-maintained instrument can enhance surgical outcomes. Consider the user experience; sometimes, the most advanced tools are not the most intuitive.

When selecting surgical instruments for 2026, several key features should be considered. Material quality is crucial. Instruments made from stainless steel or titanium offer durability and resistance to corrosion. A report by the Global Surgical Instruments Market predicts that surgical instrument sales will exceed $12 billion by 2026, underlining the importance of reliable tools.

Ergonomics play a significant role in surgical performance. Instruments designed for comfort can reduce fatigue during long procedures. A study in *Surgical Innovation* found that ergonomic handles improve user grip, leading to better precision. Steel instruments should have adequate weight for balance but not be overly heavy.

Additionally, sterility is an ongoing challenge. The design of instruments must facilitate easy sterilization processes. Instruments with fewer crevices help maintain sterility. However, many designs still fall short in this regard. As technology evolves, the integration of smart devices in instruments offers potential advantages, but concerns over data security remain. Innovation is critical, yet it must address existing limitations effectively.

Advancements in surgical instruments have significantly impacted the medical field. The use of new materials enhances durability and performance. Lightweight composites are replacing traditional metals, allowing for more precise movements during surgeries. These changes are not just technical; they also affect the comfort of the surgeon.

Technological innovations like digital tracking and enhanced optics improve visualization. Surgeons can now rely on sophisticated imaging tools integrated into instruments, providing real-time insights. However, with these advancements come questions about training. Will surgeons receive enough instruction to master these new tools? The potential is vast, but implementation could be tricky.

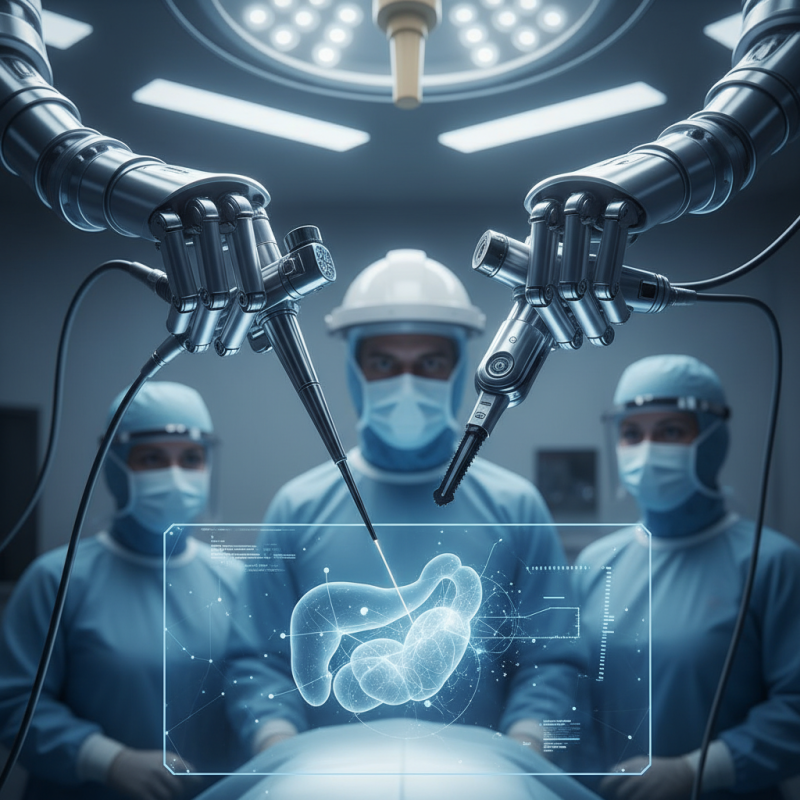

Robotic-assisted surgery is another game-changer. These systems offer precision that human hands may not replicate. Still, challenges remain. Not every surgeon may feel comfortable using robotic tools. This reliance on technology could create gaps in skills. Balancing traditional techniques with new technologies will be essential for the future.

| Instrument Type | Material | Technology Features | Weight | Durability |

|---|---|---|---|---|

| Scalpel | Titanium Alloy | Laser-etched Precision Edge | 50g | High |

| Forceps | Carbon Fiber | Non-slip Grip Technology | 30g | Medium |

| Scissors | Stainless Steel with Coating | Ergonomic Design | 40g | Very High |

| Needle Holder | Zirconium Oxide | Self-locking Mechanism | 35g | High |

| Clamp | High-grade Titanium | Advanced Grip Technology | 45g | Very High |

In the ever-evolving landscape of surgical instruments, understanding key brands and manufacturers is crucial. The surgical instrument market is projected to surpass $15 billion by 2026, reflecting robust growth. This expansion is driven by advancements in technology and an increased demand for minimally invasive surgeries. Top companies in this industry focus on innovation, quality, and precision, which are vital for surgical success.

When researching surgical instrument brands, look for those with a strong reputation for reliability. Many industry reports emphasize the importance of surgical instrument quality. Instruments must not only meet safety standards but also enhance procedural efficiency. A survey revealed that 75% of surgeons prioritize quality over cost. Instruments that fail may lead to increased surgical time and complications, impacting patient outcomes.

Tips: Assess the materials used. High-grade stainless steel or titanium is preferred for durability. Consider the ergonomics of the instruments. User-friendly designs can significantly improve surgeon comfort and control. Regularly update your knowledge on market trends to make informed purchasing decisions.

The landscape of surgical instruments is evolving rapidly. As technology advances, new trends emerge. The introduction of minimally invasive surgical procedures continues to shape instrument design. According to a recent report, the global surgical instruments market is expected to reach $25 billion by 2026. This growth reflects a rising demand for precision and efficiency in healthcare.

One key factor is the integration of robotics and AI. Surgeons benefit from enhanced precision and control. However, this trend raises questions about training and the potential for over-reliance on technology. Surgeons may need to adapt their skills continuously. Cybersecurity also becomes a concern, with connected devices vulnerable to breaches.

Tips: Choose instruments that adapt to future needs. Look for designs that prioritize user ergonomics and ease of cleaning. The longevity of materials and durability matter significantly. Always consider the balance between technology and traditional techniques. As the industry progresses, the challenges will require careful consideration and reflection.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division