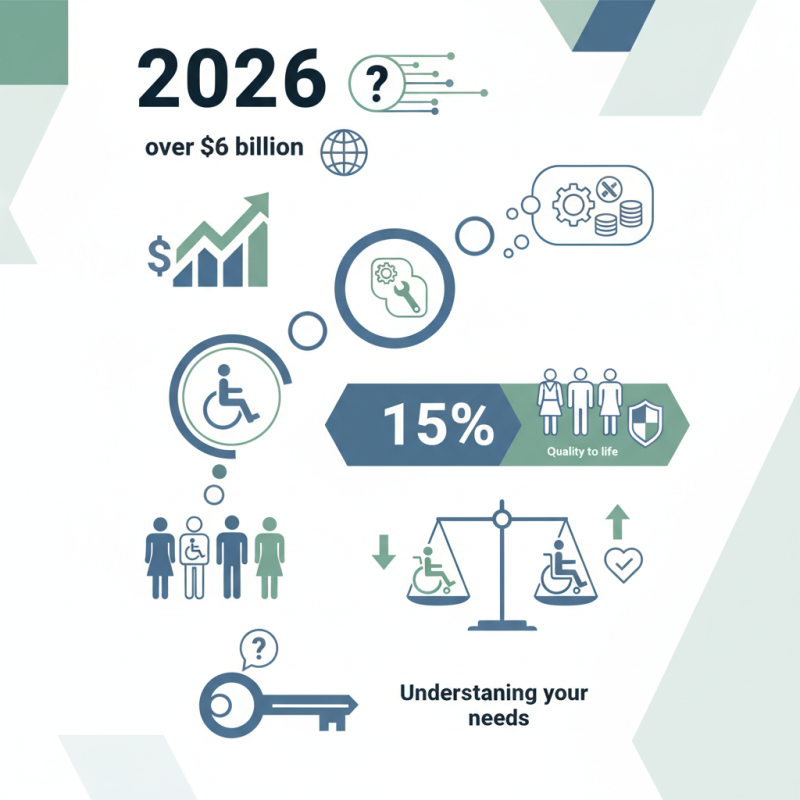

Choosing the right electric wheelchair manufacturers is crucial for users needing mobility assistance. The global electric wheelchair market is projected to reach over $6 billion by 2026, according to industry reports. This growth reveals the increasing demand for advanced mobility devices. With various options available, users may feel overwhelmed.

electric wheelchair manufacturers vary significantly in quality and features. Some focus on cutting-edge technology. Others prioritize affordability and basic functionality. A report from the World Health Organization highlights that about 15% of the global population has a disability. Thus, selecting the best manufacturer is vital for improving quality of life.

Many people often overlook essential elements when choosing a wheelchair. Service and support can differ widely among manufacturers. It is essential to remember that the cheapest option may not always be the best. Investing in a reliable manufacturer may lead to better long-term satisfaction. Ultimately, understanding your needs is a key part of this decision-making process.

When selecting an electric wheelchair manufacturer, quality should be at the forefront. High-quality manufacturing ensures reliability and longevity. Look for robust materials that withstand daily use. Pay attention to the comfort of the chair. Cushions and seat design are crucial for long-term health. A well-designed wheelchair can prevent pressure sores and improve posture.

Equally important is the attention to detail during production. Ask about the quality control measures. Are there tests before products hit the market? For many, price is a significant factor, but it's not everything. A cheaper model may compromise safety features. Some manufacturers skimp on important components. This can lead to malfunctions and accidents.

Research the manufacturer's reputation in the industry. Reviews can provide insights into performance and durability. Also, consider customer service. A responsive team can greatly enhance the user experience. Quality should always reign supreme in this life-changing decision.

When selecting an electric wheelchair, understanding key features is crucial. A recent industry report indicates that over 70% of users prioritize comfort and support. Look for adjustable seating, proper cushioning, and adequate back support. Without these, users may experience discomfort during extended use.

Battery efficiency is another vital consideration. Many electric wheelchairs offer a range of 10 to 30 miles on a single charge. However, real-life usage can impact this significantly. Users often face disappointing performances, especially if their wheelchair is heavy or has added features. Moreover, consider the chair's weight capacity. Around 20% of electric wheelchairs fail to meet the needs of larger individuals, leading to safety concerns and dissatisfaction.

Durability directly influences the long-term value of an electric wheelchair. A survey suggests that 40% of buyers regret not investing in a sturdier model. Look for materials that withstand daily wear and tear. Soft plastics or flimsy frames may not last. Reflect on your lifestyle. Will the wheelchair endure daily commutes or outdoor use? Quality matters, even if the price is higher.

When evaluating electric wheelchair manufacturers, reputation matters. A manufacturer’s standing can reflect its reliability. Look for reviews on independent platforms. Customer feedback can reveal much about product quality. Focus on detailed testimonials. These insights often highlight both strengths and weaknesses.

Some reviews are glowing, praising comfort and ease of use. Others may raise concerns about durability or customer service. Consider trends in feedback rather than isolated opinions. Watch for recurring issues. A few complaints about repair times could indicate deeper problems.

Understanding a manufacturer’s reputation can be tricky. Small companies might have limited reviews, while larger ones dominate the conversation. Balance quantity with quality. Sometimes, fewer reviews can reflect niche products that truly cater to specific needs. It’s essential to remain critical; not every positive review is genuine. Always look for depth in user experiences.

When selecting an electric wheelchair, safety standards and certifications are vital. These ensure that the device is reliable and can protect users. Key certifications include ISO, ANSI, and local safety regulations. Each of these certifications indicates a commitment to quality and safety.

Pay attention to wheelchair features. Look for models with a secure braking system. Stability is crucial for safe operation. Check for a robust construction that can handle regular wear. A device that feels sturdy can make a significant difference.

Tips: Always request documentation of safety certifications. This can provide insights into the manufacturer’s commitment to quality. Don’t hesitate to ask for user reviews as well. Real-life experiences can reveal issues that aren’t apparent in specifications alone. Remember, the cost may reflect the quality and safety of the product. Cheaper models might cut corners.

When choosing an electric wheelchair manufacturer, it’s vital to consider after-sales support and warranty options. A robust after-sales service can make a significant difference. According to industry studies, 70% of wheelchair users prioritize customer service quality when selecting a manufacturer. Inadequate support can lead to frustration and dissatisfaction.

Many manufacturers offer warranties ranging from one to five years. A longer warranty often indicates confidence in product quality. However, some manufacturers provide limited coverage. A study found that 40% of users experienced issues with their wheelchairs within two years. Without comprehensive support, these issues can be distressing.

It’s essential to ask about parts availability too. Some manufacturers have delayed response times for repairs. This can leave users stranded without their mobility aids for long periods. Consider reading customer reviews for insights on support experiences. A manufacturer’s reputation for reliability in after-sales care can often be a deciding factor.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division