Choosing the right laser equipment can be a daunting task. With various types and specifications available, selecting one that fits your needs is crucial. Industry expert Dr. Emily Black, a renowned laser technology consultant, emphasizes this point: "The right laser equipment is vital for achieving optimal results."

Understanding your specific requirements is essential. Each laser system serves different purposes. Whether for cutting, engraving, or medical applications, knowing your goals will help streamline your decision. Additionally, consider factors like budget, maintenance, and compatibility. These elements can impact your operation significantly.

However, mistakes can happen. Many buyers rush into decisions without proper research. This can lead to spending on equipment that does not fulfill their needs. Reflecting on your choices is key. An informed decision minimizes regret and maximizes efficiency. So, take the time to evaluate all aspects of laser equipment before making a commitment.

When choosing laser equipment, understanding the different types is essential. There are various types, such as CO2 lasers, fiber lasers, and solid-state lasers. Each type serves unique functions and applications. CO2 lasers are popular for cutting materials. They excel with organic substances like wood and plastics. Fiber lasers, on the other hand, are effective for metal processing. They offer precision and speed, making them ideal for industrial tasks.

Consider the specific application when selecting your equipment. For engraving delicate designs, a low-powered laser may suffice. If cutting thicker materials, a more powerful option is necessary. Reflect on the long-term needs and volume of work. It's easy to underestimate future demands, which could lead to costly adjustments later.

Always evaluate the technology level of your workspace as well. Some laser systems require advanced cooling systems or ventilation. If your environment isn't prepared, you may face challenges. Understanding the limitations and maintenance requirements of your chosen equipment is equally crucial. This choice influences not only performance but also overall efficiency. Be mindful of how these factors interact with your operational goals.

| Type of Laser Equipment | Power Output (W) | Typical Applications | Material Compatibility | Price Range (USD) |

|---|---|---|---|---|

| CO2 Laser | 40 - 300 | Wood engraving, Acrylic cutting | Wood, Acrylic, Leather | 1,000 - 10,000 |

| Fiber Laser | 20 - 1000 | Metal cutting, Marking | Steel, Aluminum, Brass | 3,000 - 50,000 |

| Diode Laser | 5 - 50 | Medical applications, Miniature engraving | Soft materials, Certain plastics | 500 - 5,000 |

| Nd:YAG Laser | 10 - 300 | Jewelry engraving, Industrial marking | Metals, Glass | 1,500 - 15,000 |

| Pulsed Laser | 30 - 500 | Precision machining, Surface treatment | Metals, Ceramics | 2,000 - 12,000 |

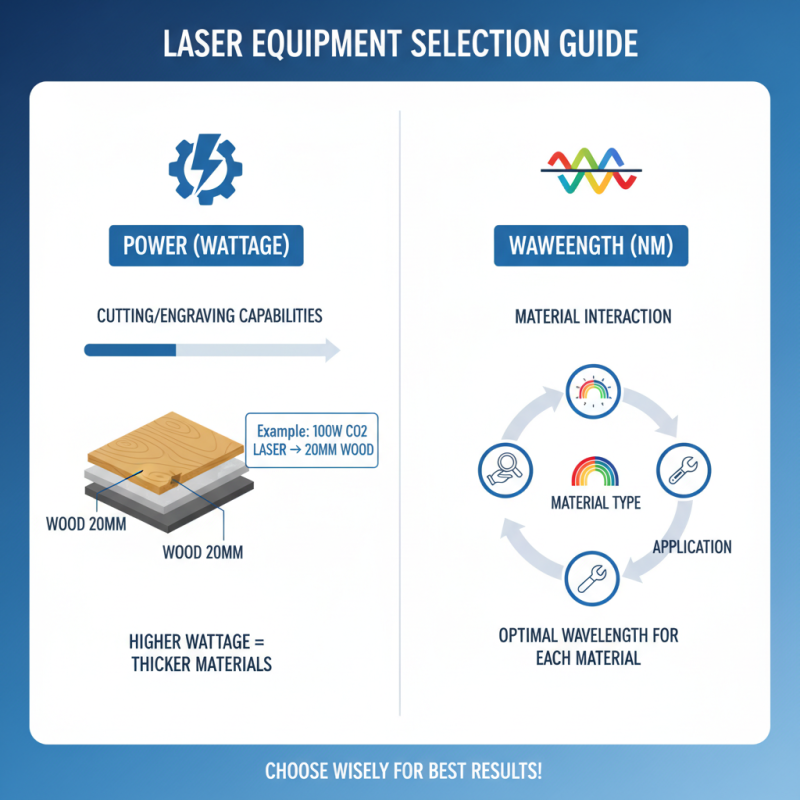

When selecting laser equipment, understanding power and wavelength is crucial. The power of a laser directly affects its cutting or engraving capabilities. According to industry reports, lasers with higher wattage can cut through thicker materials. For instance, a 100W CO2 laser can slice through wood up to 20mm thick. This understanding helps in choosing the right equipment for various applications.

Wavelength also plays a vital role in determining the laser's effectiveness. Different materials absorb specific wavelengths better. For example, a fiber laser operates at around 1064nm, making it ideal for metals. Conversely, CO2 lasers excel with non-metal materials and work best at around 10,600nm. Evaluating these factors ensures that users achieve optimal results.

However, many users overlook the right combination of power and wavelength. A laser with insufficient power may require multiple passes, increasing operational time. On the other hand, excessive power can lead to material damage. Therefore, careful consideration of both aspects must be part of the decision-making process. Misjudging these features can lead to wasted resources and unsatisfactory results.

Choosing the right laser equipment involves understanding specific features and specifications. Power output is crucial. Higher wattage means faster processing. However, more power can also mean more costs and maintenance. Consider what you really need versus what looks appealing on paper.

Wavelength affects material interaction. Different applications require different wavelengths. A laser that works for one material may not be effective for another. Adjust your choice based on the materials you plan to work with. Look into beam quality too. A high-quality beam ensures precision, which is vital in laser applications.

Don’t overlook the cooling system. Some lasers generate heat and need efficient cooling to operate safely. Air-cooled systems are simpler but can be less effective over long sessions. Reflect on your operational environment. An incompatible setup can lead to performance issues, requiring adjustments later. Adjusting your equipment is not always straightforward or easy.

When selecting laser equipment, safety must be a top priority. Many industries overlook this crucial aspect. Compliance with safety standards can prevent accidents and injuries. Research shows that 30% of laser-related incidents occur due to inadequate safety measures.

Understanding safety standards is essential. The ANSI Z136.1 standard provides guidelines for the safe use of lasers. This document outlines proper procedures and protective measures. Non-compliance can lead to costly legal repercussions. In fact, fines can exceed thousands of dollars if safety protocols are ignored.

Furthermore, the right safety features significantly impact the effectiveness of laser equipment. For instance, interlocks, warning systems, and PPE are important components. A study indicates that workplaces implementing comprehensive safety training see a 50% reduction in incidents. Companies must continuously evaluate and reflect on their safety practices. Underestimating this aspect could result in dire consequences.

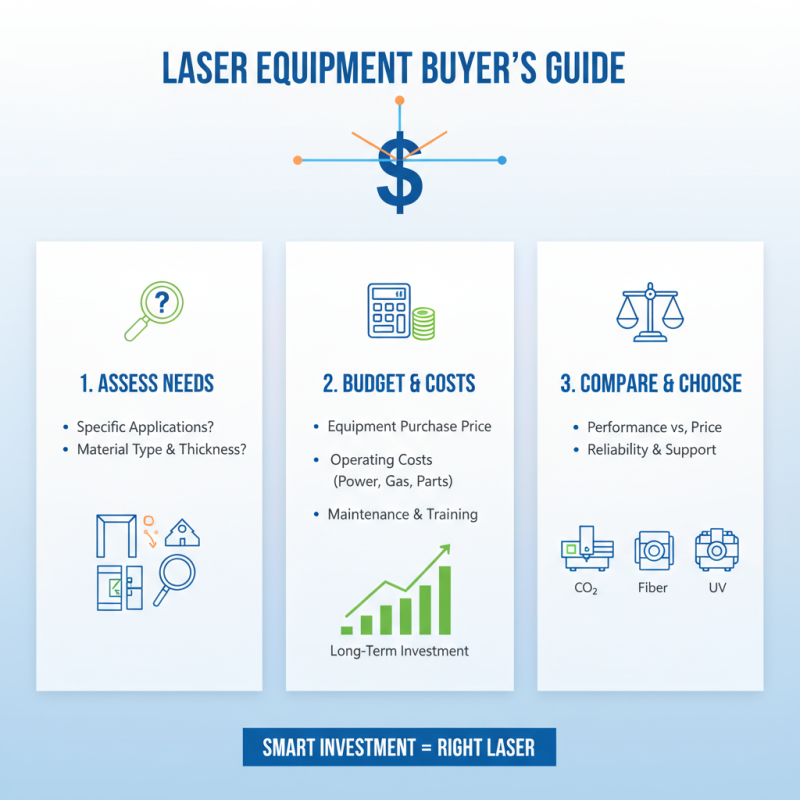

Choosing the right laser equipment requires careful budgeting and cost analysis. Start by assessing your needs. Understand the specific applications you want to use the laser for. This clarity will guide your investment choices. Keep in mind that prices can vary significantly.

Tips: Create a detailed list of features you need. Prioritize essential functions over luxury options. This can help you remain within budget while meeting your requirements.

Next, consider both initial and ongoing costs. Initial purchase price is just the start. Factor in maintenance, consumables, and energy costs. These hidden expenses can quickly add up. Analyzing total cost of ownership is crucial.

Tips: Don’t overlook financing options. Sometimes leasing can be more cost-effective. Be wary of high-interest loans. Always read the fine print before making a commitment.

Reflect on potential over-commitment. Bigger isn’t always better. An expensive piece of equipment doesn’t guarantee better results. Assess how often you'll use the equipment. This will help optimize your spending without unnecessary waste.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division