When embarking on an electronic project, one of the most critical decisions you'll face is the selection of the appropriate PCB technology. With a myriad of options available, understanding the nuances of various PCB technologies is essential to achieving both functionality and efficiency in your design. Whether you're developing a simple prototype or a complex, high-performance device, the right PCB technology can significantly impact your project's success.

Choosing the right PCB technology involves a careful assessment of your project's specific requirements, including the desired circuit density, signal integrity, thermal management, and overall production costs. As electronic devices become increasingly sophisticated, designers must navigate a landscape filled with advanced materials and manufacturing processes. This can be a daunting task, but it is crucial to identify the technology that best aligns with your needs, whether it be traditional FR-4 or emerging options like flexible or rigid-flex PCBs.

Ultimately, making an informed decision about PCB technology not only streamlines the development process but also enhances the reliability and performance of your finished product. By exploring the various PCB technologies available, you will be equipped to select the solution that delivers optimal results for your electronic projects.

When selecting the appropriate PCB technology for electronic projects, understanding the various options available is crucial. The landscape of printed circuit board technology has evolved significantly, providing designers with an array of choices tailored to different applications. According to a report by IPC, the global PCB market was valued at over $60 billion in 2020, with projections suggesting steady growth, largely driven by advancements in technology and the increasing demand for consumer electronics. As the complexity of circuits increases, so too does the need for innovative PCB solutions.

Among the prominent technologies, conventional rigid PCBs continue to dominate, especially for simple, cost-effective applications. However, the demand for flexibility has given rise to flexible and rigid-flex PCBs, which allow for intricate designs and space-saving layouts. A study by Research and Markets notes that the flexible PCB market is projected to reach $28 billion by 2025, reflecting its growing acceptance in industries such as automotive and medical equipment. Additionally, the rise of high-frequency applications has brought attention to high-frequency PCBs, which are essential for RF and microwave applications, necessitating specific materials and manufacturing processes to ensure optimal performance. Understanding these diverse technologies enables designers to choose the right PCB that meets the specific needs of their electronic projects.

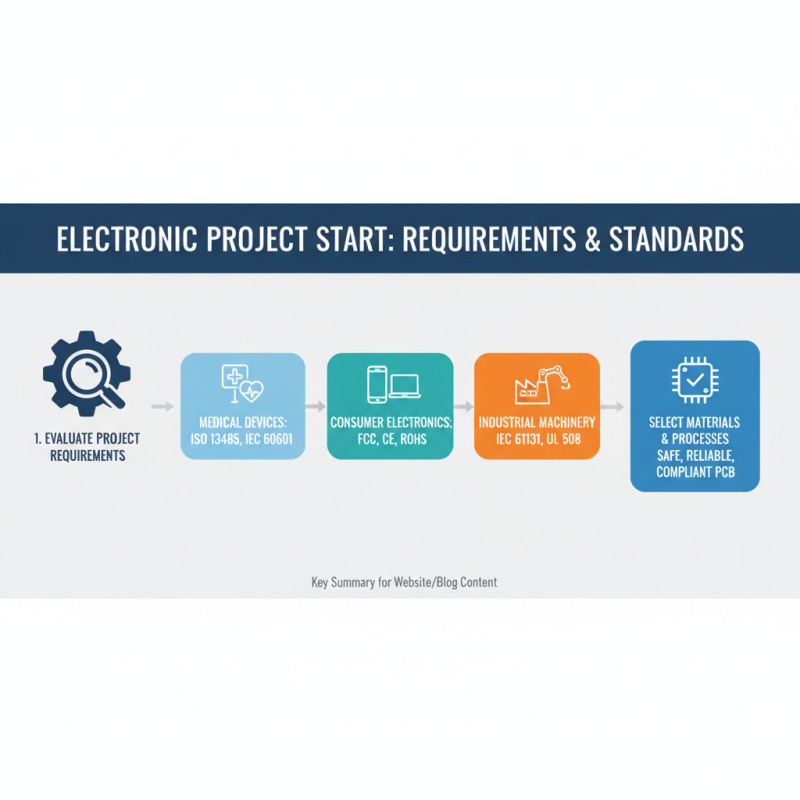

When embarking on an electronic project, the first step is to evaluate its requirements comprehensively. One of the foremost considerations is the relevant standards that apply to the specific application. For instance, whether the project will be used in medical devices, consumer electronics, or industrial machinery can determine the regulatory standards the PCB must meet. Understanding these standards helps in selecting the right materials and manufacturing processes, ensuring that the final product is safe, reliable, and compliant.

Another critical factor to consider is the size of the PCB. Projects with space constraints may necessitate more compact designs, while larger projects might allow for more elaborate layouts. Additionally, complexity plays a significant role in PCB design; simpler projects can utilize straightforward designs, but intricate functionalities demand advanced technology such as multilayer boards or high-density interconnects. Assessing the complexity will not only influence design choices but also impact manufacturing processes and costs, making it essential to align these factors with the project's overall objectives.

When embarking on an electronic project, selecting the appropriate printed circuit board (PCB) technology is crucial to ensure functionality and reliability. Single-sided PCBs are the simplest form, featuring components on only one side of the board. This makes them ideal for simple applications with limited space and lower production costs. They are widely used in basic electronics, such as small gadgets and home appliances. However, their limitations in complexity may hinder more advanced applications that require dense component layouts.

On the other hand, double-sided PCBs provide enhanced flexibility and component density by allowing placements on both sides of the board. This configuration is perfect for moderately complex designs that require more connections and a smaller footprint than single-sided boards can accommodate. They are commonly used in consumer electronics, automotive applications, and various communication devices. For projects that demand high functionality, multilayer PCBs offer the most advanced solution. Comprising multiple layers of circuitry, they facilitate intricate designs with numerous components and interconnections, all while maintaining compactness. These boards are essential for high-performance devices where signal integrity and electromagnetic compatibility are paramount, making them the go-to choice for sophisticated applications in telecommunications, medical equipment, and complex computing systems.

When selecting the right PCB technology for your electronic projects, understanding the material options is crucial. The most common choice is FR-4, a fiberglass-reinforced epoxy laminate that offers a good balance of cost, durability, and electrical performance. Its properties make it suitable for a wide range of applications, from consumer electronics to industrial devices. FR-4 PCBs are well-regarded for their rigidity and excellent dielectric characteristics, making them ideal when high performance and reliability are required in a stable environment.

In contrast, Flex PCBs provide a distinct advantage in terms of space and design flexibility. Made from flexible materials, these boards can be bent and shaped to fit into tight spaces, which is particularly useful in wearable technology and compact devices. Their lightweight nature can also contribute to overall device efficiency. However, they may come at a higher manufacturing cost and can require more careful handling and assembly processes.

Rigid-Flex PCBs combine the best features of both rigid and flexible technologies. These boards incorporate both rigid and flexible materials, allowing for innovative designs that require less interconnections and less overall assembly time. Ideal for complex applications, rigid-flex PCBs are commonly used in aerospace, military, and advanced medical devices where reliability and durability are of utmost importance. By assessing these material choices, designers can effectively tailor their PCB technology decisions to meet specific project requirements.

When selecting the right PCB technology for electronic projects, budget and manufacturing constraints play a pivotal role in decision-making. According to a report by IPC, an association for the electronics industry, over 30% of companies cited budget limitations as a significant factor influencing their choice of PCB technology. This emphasizes the need for engineers and designers to carefully evaluate manufacturing costs alongside the desired technological performance of their PCBs.

One critical aspect of budget-conscious PCB design is material selection. For example, standard FR-4 materials are often favored due to their cost-effectiveness, with reports indicating that they make up over 70% of the PCB market. However, depending on the project's specific performance requirements—such as thermal management and signal integrity—it may be worthwhile to consider alternative materials, despite their higher costs. Balancing these factors can result in a PCB that not only meets functional needs but also stays within budgetary constraints, ultimately maximizing project viability.

Additionally, manufacturing processes can significantly impact overall costs. A study by the International Electronics Manufacturing Initiative (iNEMI) revealed that optimizing the PCB layout and minimizing complexity can lead to a reduction of up to 20% in manufacturing expenses. Choosing the right technology, whether it's multi-layer boards or flexible PCBs, requires an understanding of how each choice affects both initial production costs and long-term performance. By prioritizing budget and manufacturing constraints, designers can deliver effective electronic solutions without overspending.

| PCB Technology | Cost (USD) | Lead Time (Days) | Layer Count | Common Applications |

|---|---|---|---|---|

| Single-Sided PCB | $0.10 - $2.00 | 5 - 10 | 1 | Consumer Electronics |

| Double-Sided PCB | $1.00 - $10.00 | 7 - 14 | 2 | Digital Devices, Communication |

| Multilayer PCB | $5.00 - $50.00 | 10 - 30 | 4+ | Computers, Medical Equipment |

| Rigid-Flex PCB | $10.00 - $100.00 | 15 - 45 | Varies | Aerospace, Medical, Automotive |

| High-Frequency PCB | $10.00 - $200.00 | 10 - 20 | 1 - 20 | RF Communication, Radar |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division