Choosing the right Aluminum Door Window Manufacturer in Philippines can be challenging. The market is flooded with options, making it essential to differentiate quality from mediocrity. According to industry reports, the demand for aluminum windows and doors has grown by 15% annually. This growth reflects the rising interest in modern construction materials that offer durability and aesthetic appeal.

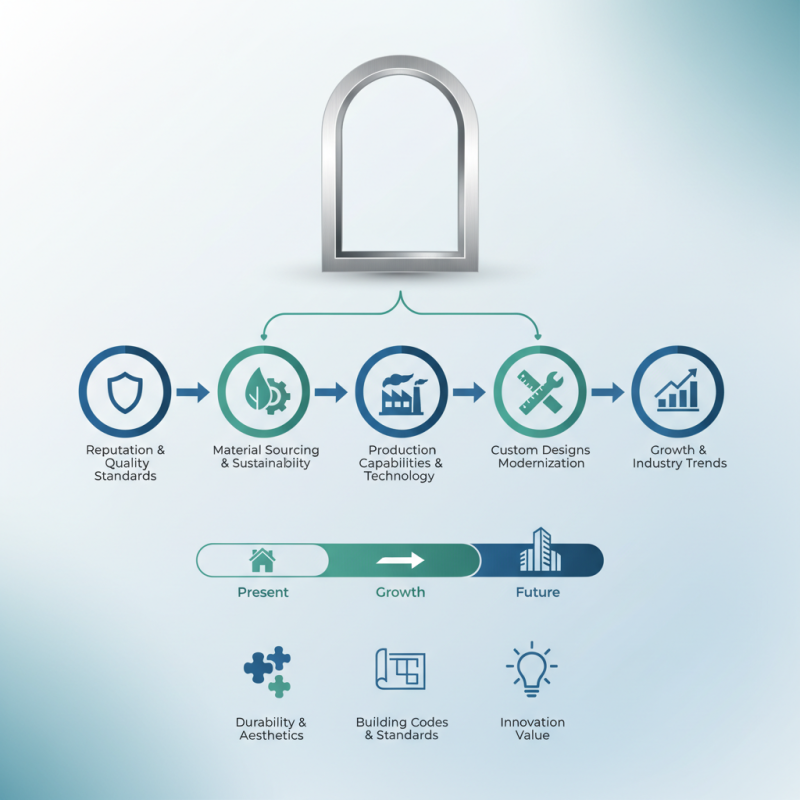

Not all manufacturers maintain high standards. Some may cut costs, sacrificing quality for a lower price. It's vital to examine a manufacturer's reputation, material sourcing, and production capabilities. The right factory ensures that products meet international quality standards and local building codes. Additionally, look for manufacturers that offer custom designs tailored to your specific needs, as this can enhance your project's overall look and functionality.

The industry is ever-evolving, with new technologies emerging. Manufacturers should embrace innovation to stay competitive. As you explore your options, prioritize sustainability as well. Reports indicate that eco-friendly practices can enhance brand value. This is an aspect worth reflecting on as you choose your Aluminum Door Window Manufacturer in Philippines.

The Philippine aluminum door and window market is experiencing notable growth. This trend is driven by urbanization and increasing construction activities. More homeowners prefer aluminum for its durability and aesthetic appeal. Aluminum doors and windows offer better insulation compared to traditional materials. This is crucial in a tropical climate like the Philippines.

Many manufacturers are entering the market, aiming to meet rising demand. However, not all offer the same quality. Some products lack durability and have poor finishes. It's important for buyers to conduct thorough research. Look for manufacturers with a track record of quality and customer satisfaction. Customer reviews can provide insights into durability and service.

The competition can be fierce, leading to unfinished products. Price is not always an indicator of quality. Buyers may feel overwhelmed by choices. It's advisable to seek samples before finalizing a purchase. Understanding market trends can help consumers make informed decisions in this evolving landscape.

Choosing the right aluminum door and window manufacturer in the Philippines can be challenging. Start by evaluating their experience in the industry. A manufacturer with over ten years of experience often provides better quality. Some reports indicate that established companies achieve an average customer satisfaction rate of 85%. This can signal reliability and trustworthiness.

Next, assess the materials used. High-quality aluminum alloys are crucial. Manufacturers should use 6063 or 6005 aluminum, known for its strength and corrosion resistance. Many customers overlook this detail, focusing instead on design. But upgrades in material often lead to longer-lasting products.

Another key factor is customer service. A company that prioritizes communication can make a big difference. Reports show that 70% of customers value prompt responses. If inquiries take too long, it might signal underlying issues. Installation services are also essential. Some manufacturers miss providing adequate guidelines, leading to poor installations and disappointing results. Look for companies that offer comprehensive support throughout the buying process.

When choosing an aluminum door window manufacturer in the Philippines, quality standards are crucial. Look for certifications that demonstrate a commitment to excellence. ISO certifications are vital. They assure that manufacturers adhere to international quality benchmarks. This gives you confidence in the product's durability and performance.

Another important aspect is checking for local standards. The Bureau of Philippine Standards provides guidelines for various materials. Manufacturers that comply with these standards show they prioritize safety and quality. Visiting manufacturing facilities can also reveal their quality control processes. Ask about testing methods used for materials and products.

Keep in mind that not all manufacturers share their certifications openly. Some may have outdated information or incomplete documentation. A little skepticism can go a long way. Inspecting product samples before making decisions can also be beneficial. The feel and finish can tell you much about the manufacturer’s attention to detail.

When selecting an aluminum door window manufacturer in the Philippines, pricing models often vary significantly. It is essential to compare quotes from multiple suppliers. Some manufacturers provide lower prices but might use inferior materials. This could result in poor durability over time. It’s wise to examine what each quote includes. Look for warranties or service agreements that add value to the overall package.

Value propositions can paint a clearer picture. A higher upfront cost may lead to long-term savings if the product lasts longer. Some manufacturers offer customization options. This means you can have doors and windows tailored to your specific needs, but it may increase the price. Consider the balance between your budget and desired specifications.

Do not overlook customer service. A supplier that is responsive can make a big difference. Reflect on your experiences or those of others when working with different manufacturers. It might expose unexpected costs or issues in after-sales support. Aim for a supplier that offers both quality products and reliable service to ensure a successful investment.

When selecting an aluminum door and window manufacturer in the Philippines, customer reviews play a crucial role. Authentic feedback often reflects the reliability of a manufacturer. Happy clients usually share their positive experiences online. However, it’s also essential to consider negative reviews. They reveal potential issues like delayed deliveries or poor customer service. Observing patterns in reviews can help assess credibility.

Don’t rely solely on average ratings. Deep dive into individual testimonials. Look for detailed accounts about product quality and after-sales support. Some customers might highlight helpful staff or superior installation processes. Others could share their dissatisfaction with materials used. Accent these red flags early on to avoid disappointment.

It’s valuable to interact with past clients if possible. Their firsthand experiences can provide insights into how the manufacturer addresses concerns. This can be a decisive factor. Unresolved complaints in reviews may indicate deeper issues. Keep an eye out for how manufacturers respond to criticism. Their reactions often reveal their commitment to customer satisfaction, which is critical for your investment.

| Criteria | Rating (1-5) | Customer Feedback |

|---|---|---|

| Product Quality | 4.5 | Durable and long-lasting products with excellent finishing. |

| Customer Service | 4.2 | Responsive and helpful support throughout the purchase process. |

| Pricing | 4.0 | Competitive prices compared to other manufacturers. |

| Delivery Time | 4.3 | Timely deliveries with clear communication. |

| Warranty Offered | 4.4 | Comprehensive warranty that covers major issues. |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division