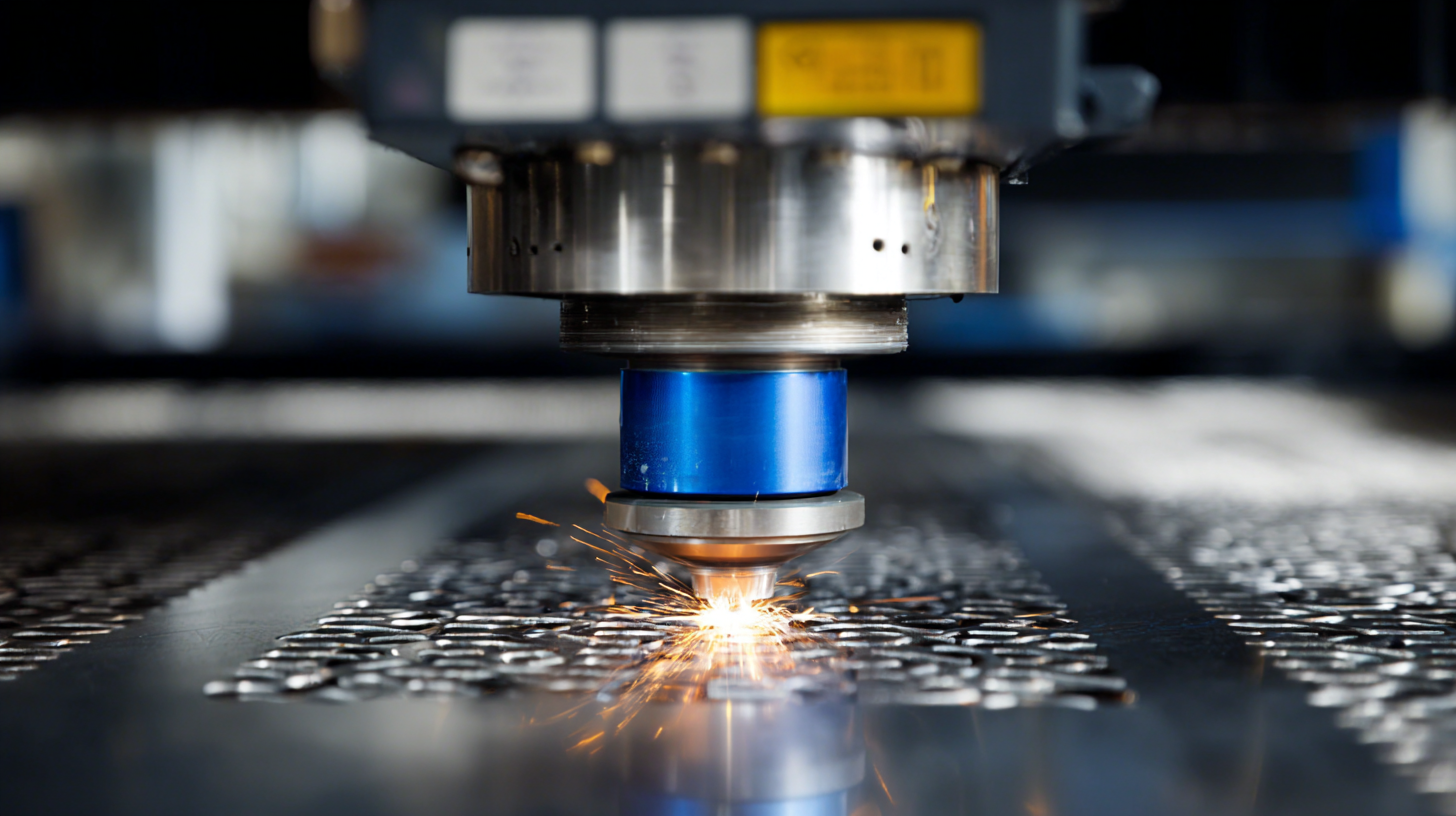

As the global manufacturing landscape continues to evolve, the role of advanced technologies such as laser machines has become increasingly pivotal. According to a recent report by MarketsandMarkets, the laser cutting machine market is projected to reach $4.68 billion by 2025, driven by the demand for precision manufacturing across various sectors including automotive, aerospace, and electronics. China stands at the forefront of this revolution, emerging as a trusted global manufacturing partner for premier laser solutions. By harnessing cutting-edge technology and streamlined production processes, Chinese manufacturers are not only improving the efficiency of laser machines but also enhancing their capabilities in various applications. This blog will explore how partnering with these premier laser solution providers can empower businesses worldwide to achieve superior performance and innovation.

Premier Laser Solutions is rapidly establishing itself as a leading global manufacturing partner, particularly in the field of laser technology. As the market for laser processing equipment is projected to grow from $28.51 billion in 2025 to a staggering $64.39 billion by 2032, with a compound annual growth rate (CAGR) of 12.3%, the demand for innovative and reliable laser solutions has never been higher. This momentum is further bolstered by the trends in the laser hair removal market, expected to reach a value of $14.2 billion in 2025 and surge to $46 billion by 2032.

In light of these developments, it is essential for businesses to stay informed about the latest advancements in laser technology. **Tip:** Regularly attending global industry conferences, such as those focusing on intelligent manufacturing, can provide insights into emerging trends and foster valuable networking opportunities.

Furthermore, the fiber laser market is also witnessing significant growth, with an anticipated increase from $4.63 billion in 2025 to $10.75 billion by 2032. This impressive CAGR of 12.8% reflects the rising adoption of fiber lasers in various industrial applications. **Tip:** Companies should consider investing in fiber laser technology to enhance operational efficiency and product quality in manufacturing processes.

In the ever-evolving landscape of advanced industries, laser technology is witnessing significant innovations, especially from China, which is establishing itself as a formidable player globally. Key technical specifications of laser products are crucial for ensuring their effectiveness in various applications, from telecommunications to manufacturing. According to a recent industry report, the market for quantum dot lasers is expected to grow steadily, with over 30 key players actively shaping the sector. This indicates a growing interest in advanced laser solutions due to their superior performance and efficiency.

Furthermore, advancements in free-space optical communication (FSOC) technology are revolutionizing data transfer capabilities, promising high data rates and enhanced connectivity. With the increasing demand for optical transceivers designed for long-range applications, precision temperature control has become a critical factor in maintaining laser stability. In sectors such as laser dentistry, AI integration is further enhancing precision and outcomes, reflecting the trend towards intelligent, innovative solutions in laser technology.

These developments not only showcase China's capabilities but also underline the importance of robust technical specifications in the global laser manufacturing landscape.

When selecting the right laser solution for your business, it's essential to consider your specific needs and the diverse applications of laser technology. The global laser technology market is projected to reach $15.99 billion by 2027, with a compound annual growth rate of 4.5% in the upcoming years. This growth signals the expansive potential for businesses to leverage laser solutions across various industries, from manufacturing to medical applications.

One significant area witnessing rapid development is the laser processing equipment market, expected to grow from $28.51 billion in 2025 to $64.39 billion by 2032, at an annual growth rate of 12.3%. Companies must assess their operational requirements and align them with effective laser processing options. Furthermore, veterinary laser therapy is also on the rise, illustrating the versatility of laser applications; the market is anticipated to grow from $650 million in 2025 to over $1.24 billion by 2033. Understanding these trends can help businesses make informed decisions when choosing the ideal laser solutions to enhance efficiency and support innovation.

Partnering with Premier Laser Solutions offers a myriad of benefits that cater to the evolving needs of manufacturers in today’s fast-paced market. With an annual growth rate of 9.1% projected for the global laser processing market, expected to reach $18.2 billion by 2025, collaborating with a trusted partner like Premier Laser Solutions can facilitate entry into this lucrative sector. Their cutting-edge technology and expertise in laser fabrication not only enhance product quality but also improve efficiency, enabling companies to stay competitive.

Moreover, Premier Laser Solutions emphasizes customization and innovation, which are vital in a market where 75% of customers prefer products tailored to their specific needs. By leveraging their advanced laser technology, manufacturers can achieve precision in production, leading to reduced waste and lower operational costs. Additionally, their strategic location in China allows for streamlined supply chain management and access to high-quality materials at competitive prices, further driving down expenses while maintaining superior quality. Engaging with Premier Laser Solutions not only optimizes production but also positions investors advantageously in a rapidly growing industry.

The global laser cleaning market is set to witness significant growth, projected to reach $1.15 billion by 2032, with a compound annual growth rate (CAGR) of 6.36% from 2024 to 2032. This uptick underlines the increasing adoption of laser technology across various industries, emphasizing the innovation and efficiency that lasers can bring to crucial manufacturing processes. As companies strive for higher standards in quality and sustainability, laser applications present an effective solution for cleaning and maintenance that traditional methods may not match.

In Chengdu, the transportation sector exemplifies the transformative power of laser technology, particularly with the introduction of robotic repair systems for rail vehicles. These advancements enhance operational efficiency and showcase how AI and laser solutions are unlocking new growth avenues within industrial applications. Bulletproofing the future of industries, laser technology not only contributes to automation but also acts as a catalyst for innovation, encouraging businesses to explore further enhancements in productivity and quality control methodologies.

| Industry | Laser Application | Technology Type | Advantages |

|---|---|---|---|

| Automotive | Welding | Fiber Laser | High precision, speed, and reduced heat affected zone. |

| Aerospace | Cutting | CO2 Laser | Ability to cut complex shapes with high accuracy. |

| Medical | Surgery | Ultrafast Laser | Minimal invasiveness and precision in tissue removal. |

| Manufacturing | Marking | YAG Laser | Durable and high-quality markings on various materials. |

| Electronics | Engraving | Fiber Laser | High speed and precision for intricate designs. |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division