As we look ahead to 2025, the laser technology industry is poised for remarkable advancements driven by innovations and applications across various fields. According to a recent report by MarketsandMarkets, the global laser technology market is expected to reach $13.22 billion by 2025, growing at a CAGR of 5.6% during the forecast period. This growth is fueled by the increasing adoption of laser technologies in manufacturing, healthcare, and telecommunications. Additionally, the demand for precision instruments in sectors such as aerospace and automotive is propelling the evolution of high-powered laser solutions. With trends like the integration of artificial intelligence and the expansion of solid-state lasers gaining traction, understanding these emerging technologies is essential for stakeholders seeking to stay competitive. This blog will explore how to navigate the upcoming trends in laser technology, providing insights that can aid businesses in leveraging these advancements effectively.

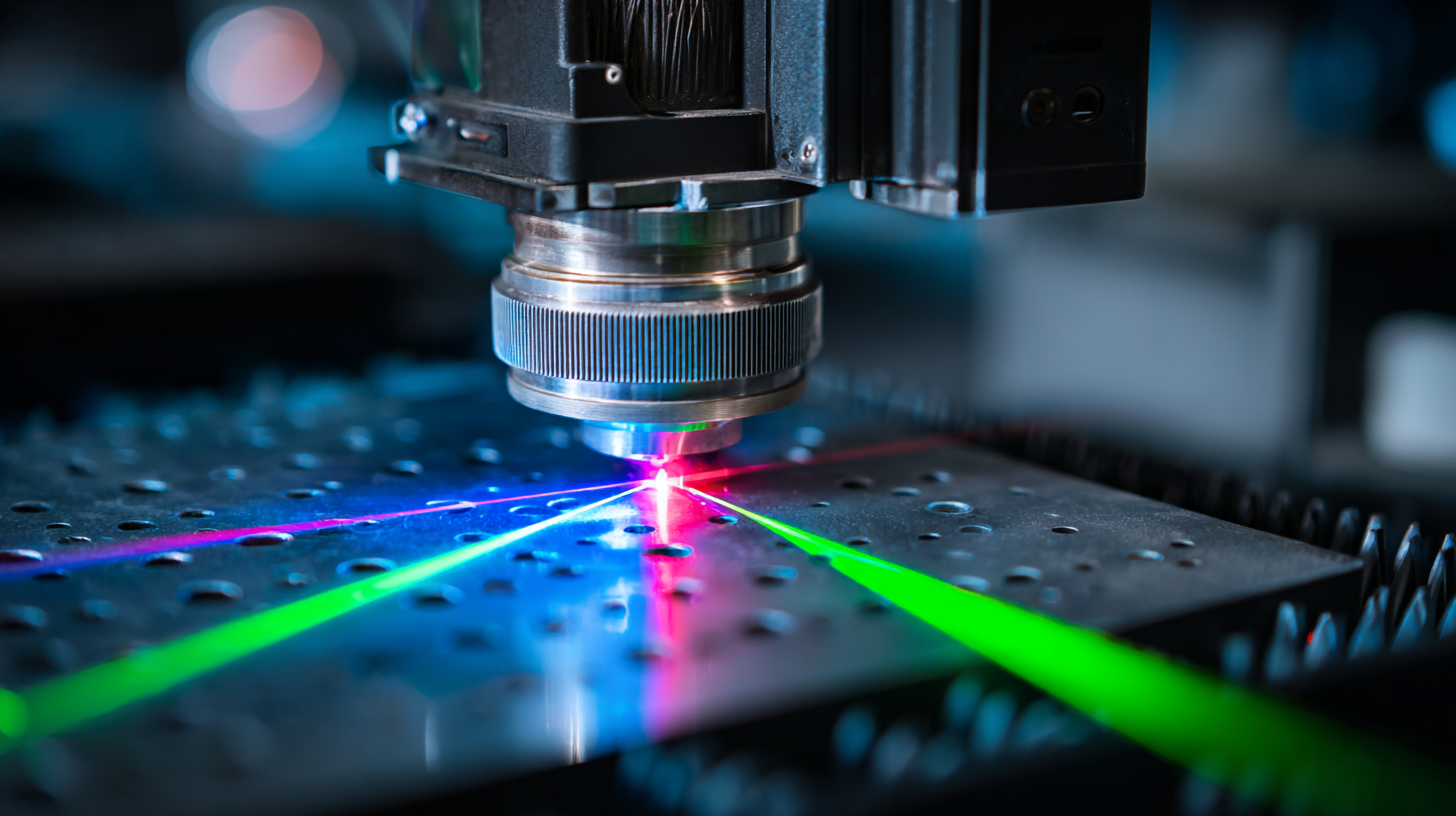

The landscape of laser technology is evolving rapidly, especially as we approach 2025. Among the various types of lasers, CO2 and fiber lasers continue to be at the forefront, each offering unique advantages that cater to different industrial applications. According to recent market analysis, the laser marking segment is expected to witness substantial growth, with fiber lasers dominating due to their versatility and efficiency in high-speed operations. Data indicates that the fiber laser market is projected to reach significant value, outpacing other types through 2030.

When comparing CO2 lasers to fiber lasers, it's essential to consider their operational strengths. Fiber lasers excel in precision cutting and engraving, making them highly suitable for metals and a wide range of materials. In contrast, CO2 lasers are favored for cutting non-metallic materials and achieving smoother finishes. A study highlighted that CO2 lasers can reduce surface roughness by up to 85% in applications such as laser polishing of aluminum alloys. This indicates that despite the increasing popularity of fiber lasers, CO2 lasers maintain a vital role in specific production processes where material compatibility is key.

As the industry looks forward, ongoing advancements in laser technology will likely lead to further innovations, enhancing performance and expanding the capabilities of both CO2 and fiber lasers. The continued investment in research and development promises exciting future applications that could redefine manufacturing practices across various sectors.

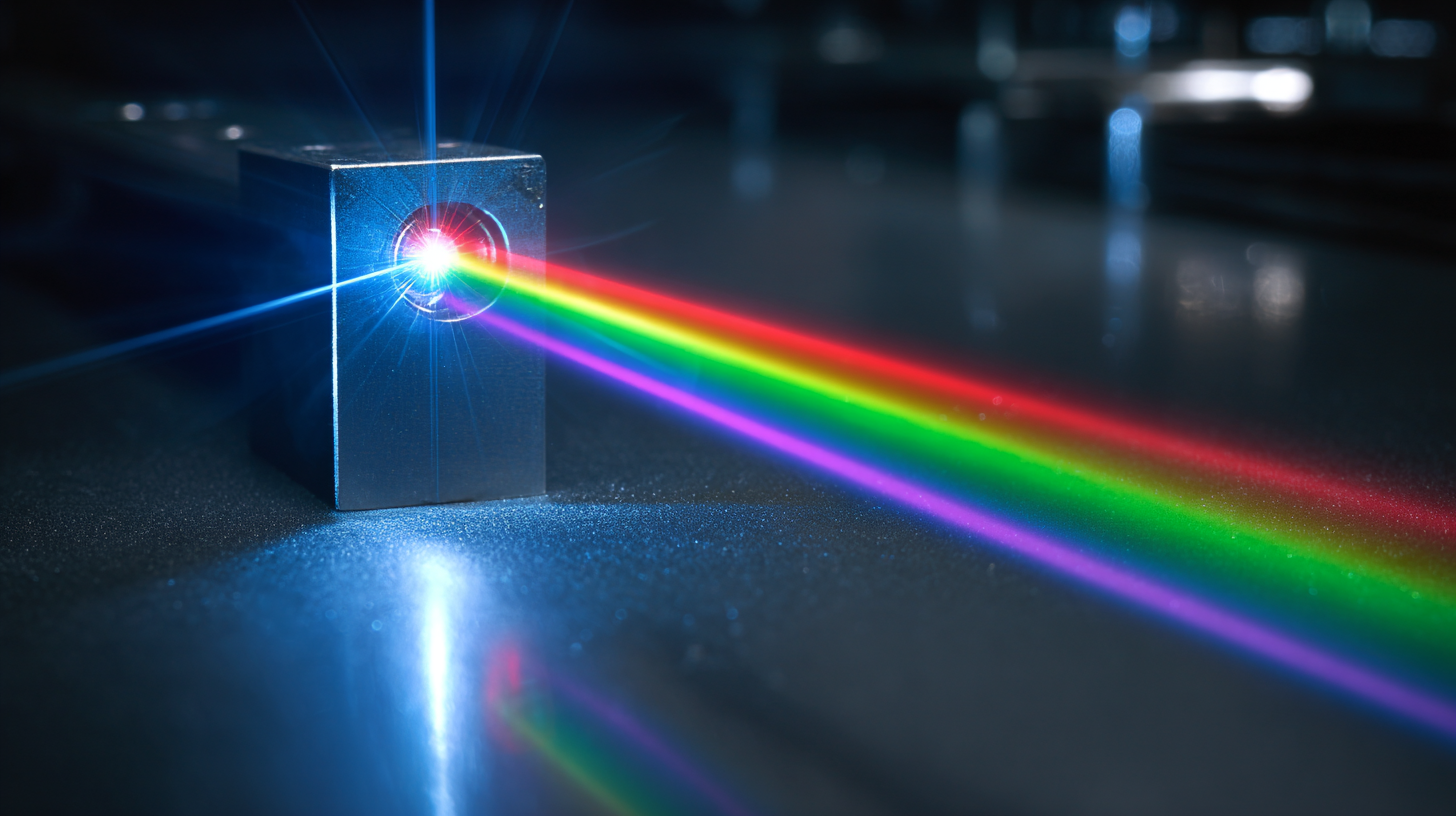

The landscape of laser technology is evolving rapidly, with significant innovations shaping the future. At the forefront of these advancements are

solid-state and gas lasers, each offering unique benefits and applications that cater to diverse industry needs.

Solid-state lasers have gained prominence due to their compact size, efficiency, and high output power. They are increasingly employed in fields like materials processing, medical procedures, and telecommunications,

where precision and reliability are paramount. Advancements in solid-state materials, such as new gain media and improved cooling systems, are further enhancing their performance

and expanding their capabilities.

On the other hand, gas lasers, notably CO2 and excimer lasers, continue to play a vital role in specific applications. Their ability to produce intense beams suitable for cutting, engraving, and medical applications remains unmatched.

Recent developments in gas laser technology, including advancements in beam quality and control, are making them more versatile. For instance, innovations in hybrid systems that combine

gas and solid-state technologies are emerging, allowing for enhanced flexibility and efficiency in manufacturing processes. As laser technology continues to advance, the competition between solid-state

and gas lasers will drive the industry towards further innovation and efficiency, ensuring that both technologies find their place in the future of various applications.

As we approach 2025, the laser technology industry is on the cusp of significant evolution, particularly in cost-effectiveness across various types of lasers. A recent report by MarketsandMarkets projects that the global laser market will grow from $15 billion in 2020 to over $25 billion by 2025, driven largely by advancements in efficiency and reductions in operational costs. In this context, understanding the capital and operational expenses associated with different laser types is essential for businesses aiming to remain competitive.

For instance, fiber lasers have become increasingly popular due to their relatively low operational costs and high efficiency, often leading to savings of up to 30% over traditional CO2 laser systems. Moreover, the initial capital investment, while higher in some cases, is offset by the lower maintenance fees and longer lifespan. It’s crucial for companies to conduct thorough cost analyses, weighing the long-term benefits against the upfront investment.

Tip: When selecting a laser system, consider not just the purchase price but also the total cost of ownership, including energy consumption and maintenance. Additionally, staying informed about the latest innovations can reveal emerging products with enhanced cost-efficiency features that may further optimize operational budgets.

As industries prepare for 2025, advancements in laser technology are set to redefine performance benchmarks, particularly in speed, precision, and versatility. Recent analysis from the International Laser Display Association indicates that by 2025, laser systems will achieve processing speeds increased by 30% compared to current standards, driven by innovations in laser sources and beam control technologies. Precision is also on the rise, with new models boasting an accuracy level of up to 0.01 mm, enhancing capabilities in fields like aerospace and medical device manufacturing where precision is paramount.

Tips for selecting laser technology: When evaluating laser systems, consider the specific application requirements. For tasks that demand high precision, such as micro-machining, invest in models that feature adaptive optics. Additionally, versatility is crucial; multi-functional laser systems can drastically reduce operational costs by consolidating multiple processes into one. Lastly, ensure that the technology you choose provides real-time performance data for better decision-making and efficiency analysis.

Emerging trends also show that eco-friendly laser technologies are on the rise, with reports indicating that, by 2025, over 40% of laser devices will utilize green energy sources. This not only contributes to sustainability goals but also minimizes operational costs in the long run. Understanding these performance metrics will help businesses leverage laser technology effectively in a competitive landscape.

| Laser Technology Type | Speed (m/min) | Precision (μm) | Versatility (Applications) | Cost Efficiency ($/m) |

|---|---|---|---|---|

| Fiber Laser | 30 | 5 | Metals, Plastics, Wood | 0.15 |

| CO2 Laser | 25 | 10 | Wood, Acrylic, Fabrics | 0.20 |

| Diode Laser | 35 | 15 | Plastics, Metals, Skin | 0.10 |

| Solid-State Laser | 20 | 8 | Glass, Metals, Ceramics | 0.25 |

| Ultrafast Laser | 15 | 2 | Medical, Micro-manufacturing | 0.30 |

As we move towards 2025, various industries are increasingly leveraging advanced laser technologies to enhance their operational efficiency and product quality. In the field of manufacturing, fiber lasers have gained popularity due to their precision and speed. They are particularly effective for cutting and engraving metals, making them indispensable in the automotive and aerospace sectors. The ability of fiber lasers to operate on thicker materials with minimal distortion has revolutionized these industries, allowing for complex designs and tighter tolerances.

Meanwhile, in the healthcare sector, the emergence of ultrafast lasers is paving the way for groundbreaking applications in both diagnostics and treatment. These lasers can generate extremely short pulses of light that are capable of targeting tissues with remarkable accuracy, enabling non-invasive procedures and reducing recovery times for patients. This technology is particularly beneficial in ophthalmology for procedures such as LASIK, as well as in dermatology for skin resurfacing treatments, proving that the adaptability of lasers can meet the unique demands of diverse medical applications.

In the realm of telecommunications, semiconductor lasers are ushering in an era of faster data transmission. Their compact size and efficiency make them ideal for enabling high-speed internet and improving overall network performance. This advancement indicates a significant leap towards the realization of smart cities and the Internet of Things, demonstrating how different laser technologies are not only innovating traditional practices but are also shaping the future landscape of multiple industries.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division