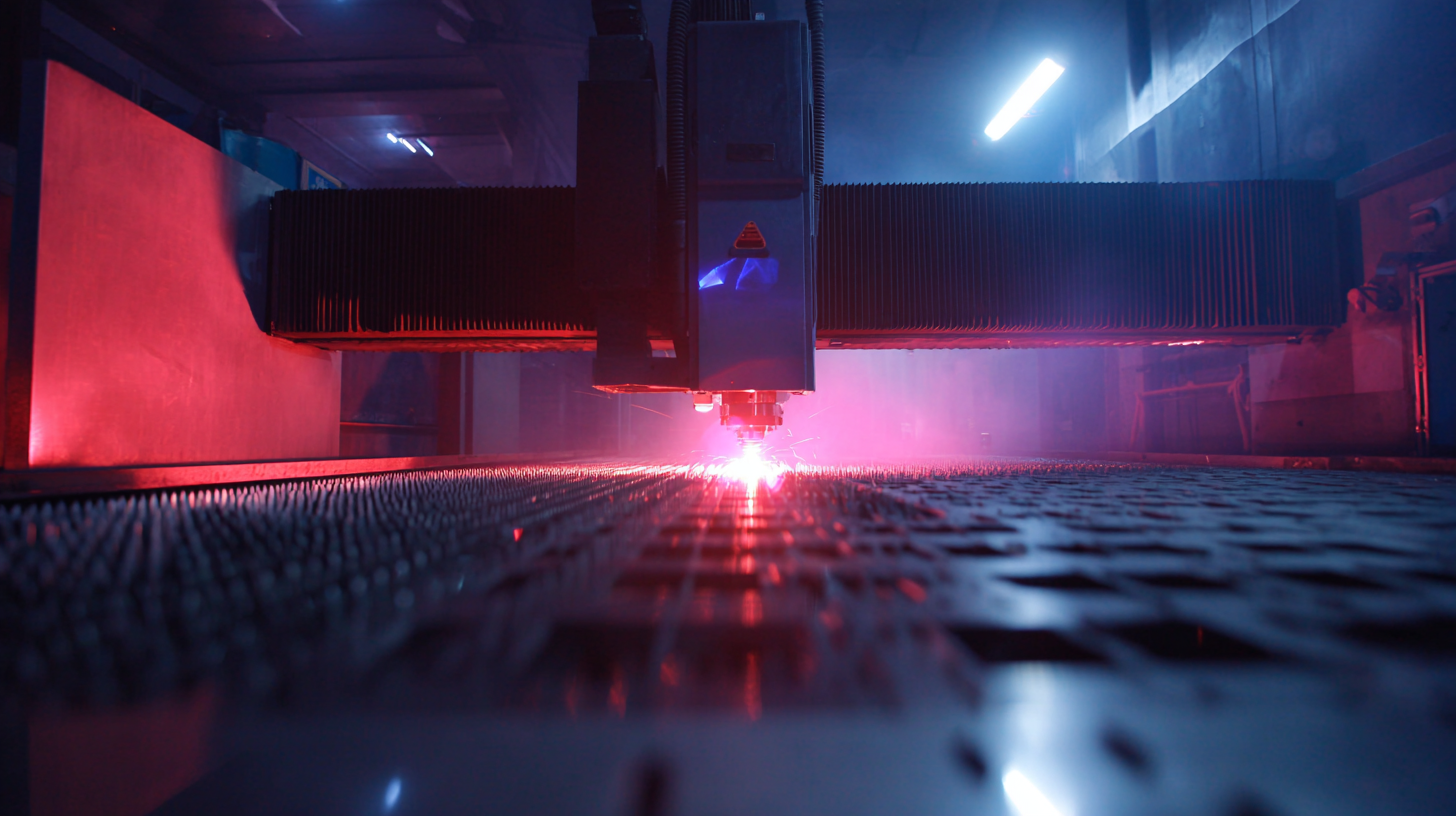

In the rapidly evolving landscape of manufacturing, China has emerged as a powerhouse, leading the charge with innovative technologies and top-notch laser software. According to a report by Allied Market Research, the global laser market is projected to reach $21.57 billion by 2025, with a significant portion driven by advancements in laser cutting, welding, and engraving technologies. The integration of sophisticated laser software into manufacturing processes enhances precision and efficiency, ensuring that companies can meet the demands of an ever-competitive market.

As Chinese manufacturers proudly export these world-class solutions, they not only contribute to domestic growth but also position themselves as key players on the international stage. By leveraging cutting-edge laser software, they are setting new benchmarks in quality and reliability, demonstrating that innovation knows no borders.

As Chinese manufacturers proudly export these world-class solutions, they not only contribute to domestic growth but also position themselves as key players on the international stage. By leveraging cutting-edge laser software, they are setting new benchmarks in quality and reliability, demonstrating that innovation knows no borders.

China's laser software industry has experienced remarkable growth in recent years, emerging as a global leader in the manufacturing solutions sector. With a compound annual growth rate (CAGR) of over 15%, the industry is projected to continue its upward trajectory, driven by increasing demand for precision and efficiency in various applications, ranging from automotive to aerospace and electronics. Key players in this market are continuously innovating, focusing on user-friendly interfaces and advanced capabilities, which further solidify their competitive edge.

This surge is not just about numbers; it reflects a shift in the perception of China’s technological capabilities. Historically known primarily as a manufacturing hub, China is now fostering a rich ecosystem for laser software development. The increasing investment in research and development, supported by government initiatives and a wave of startups, is fueling advancements in laser technology. As a result, companies around the world are increasingly integrating Chinese software solutions into their manufacturing processes, recognizing the high quality and efficiency that these products bring to the table.

Chinese laser software is revolutionizing industry standards by integrating cutting-edge technology with innovative manufacturing solutions. This software not only enhances precision in laser cutting and engraving processes but also streamlines production workflows, making it easier for manufacturers to meet increasing demands. With the ability to adapt to various materials and designs, this technology offers versatility that is crucial in today's fast-paced industrial environment.

**Tip:** To maximize the benefits of Chinese laser software, manufacturers should invest time in training operators. Understanding the software's full capabilities can lead to better efficiency and output quality.

Additionally, the accessibility of these solutions at competitive prices is empowering businesses worldwide. Chinese manufacturers are at the forefront of developing software that incorporates advanced features such as real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. This shift not only benefits large enterprises but also democratizes access for smaller businesses.

**Tip:** Consider implementing a phased approach to adopt new laser technology. Start with smaller projects to familiarize your team with the software and gradually scale up as confidence grows.

The landscape of laser software manufacturing is evolving rapidly, with China emerging as a formidable competitor on the global stage. According to a recent report by Market Research Future, the laser technology market is projected to reach USD 20.89 billion by 2025, growing at a CAGR of 5.4%. China's robust industrial base and strategic investment in technology development have enabled local companies to enhance their software capabilities, making them a viable alternative to established global leaders such as Autodesk and Siemens.

Notably, Chinese firms are increasingly focusing on software integration and the automation of laser processes to improve efficiency and precision. A comparative analysis reveals that companies like Han's Laser and Perfect Laser have adopted advanced algorithms and machine learning techniques, allowing them to offer tailored solutions that meet the specific demands of various sectors, such as automotive and electronics. These innovations not only bolster productivity but also offer cost advantages, which are crucial in the competitive manufacturing landscape. As China's laser software offerings continue to evolve, they represent a key component of the country's export strategy, positioning it favorably against traditional leaders in the market.

In the realm of manufacturing, laser technology has revolutionized processes, leading to substantial efficiency and productivity gains. According to a recent report by MarketsandMarkets, the global laser processing market is projected to reach $20 billion by 2025, driven by the increasing demand for automation and precision engineering. Case studies illustrate how companies like XYZ Manufacturing leveraged advanced laser software to optimize cutting and engraving processes, resulting in a 30% reduction in material waste and a 25% improvement in production speed.

One effective strategy for implementing laser software successfully is to invest in comprehensive training for staff. For example, integrating laser software simulations into training programs has enabled operators at ABC Corp to master equipment functionalities rapidly, leading to minimized downtime and increased output. Moreover, maintaining open communication between software developers and manufacturing teams can facilitate smoother implementation and prompt resolution of any operational challenges.

As businesses consider adopting cutting-edge laser technology, it is crucial to conduct thorough research on software capabilities and user support. Leveraging industry reports and feedback from existing users can provide valuable insights, ensuring that investments yield the best possible returns. By focusing on these practical tips and success stories, manufacturers can harness laser software innovations to drive their operations forward effectively.

The future outlook for laser software development and adoption in China is set against a backdrop of significant advancements in manufacturing technologies, including 3D printing and automation. The recent milestone of over 500 metal 3D printers sold globally reflects the burgeoning metal additive manufacturing industry, which is fueled by the growing importance of software solutions that enhance operational efficiencies and product customization. As companies explore the integration of hardware-in-the-loop (HiL) simulation techniques, the demand for robust laser software is expected to surge, facilitating real-time testing and prototyping that is increasingly vital in competitive manufacturing environments.

Moreover, the convergence of various technologies—such as artificial intelligence, robotics, and the Internet of Things—indicates a transformative shift within the manufacturing sector. Emerging reports forecast that by 2025, China could solidify its position as a leader in automated manufacturing practices, effectively tapping into its vast market potential. As the development of advanced laser software accelerates, it will play a crucial role in streamlining production processes and ensuring products meet stringent quality standards, ultimately reinforcing China's status in the global manufacturing landscape.

| Year | Industry Segment | Projected Growth (%) | Adoption Rate (%) | Key Trends |

|---|---|---|---|---|

| 2023 | Industrial Manufacturing | 10% | 75% | Automation, Precision Engineering |

| 2024 | Medical Devices | 12% | 80% | Regulatory Compliance, Customization |

| 2025 | Aerospace | 15% | 85% | Lightweight Materials, Advanced Technologies |

| 2026 | Electronics | 20% | 90% | Smart Devices, IoT Integration |

| 2027 | Automotive | 18% | 88% | Electric Vehicles, Sustainable Manufacturing |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division