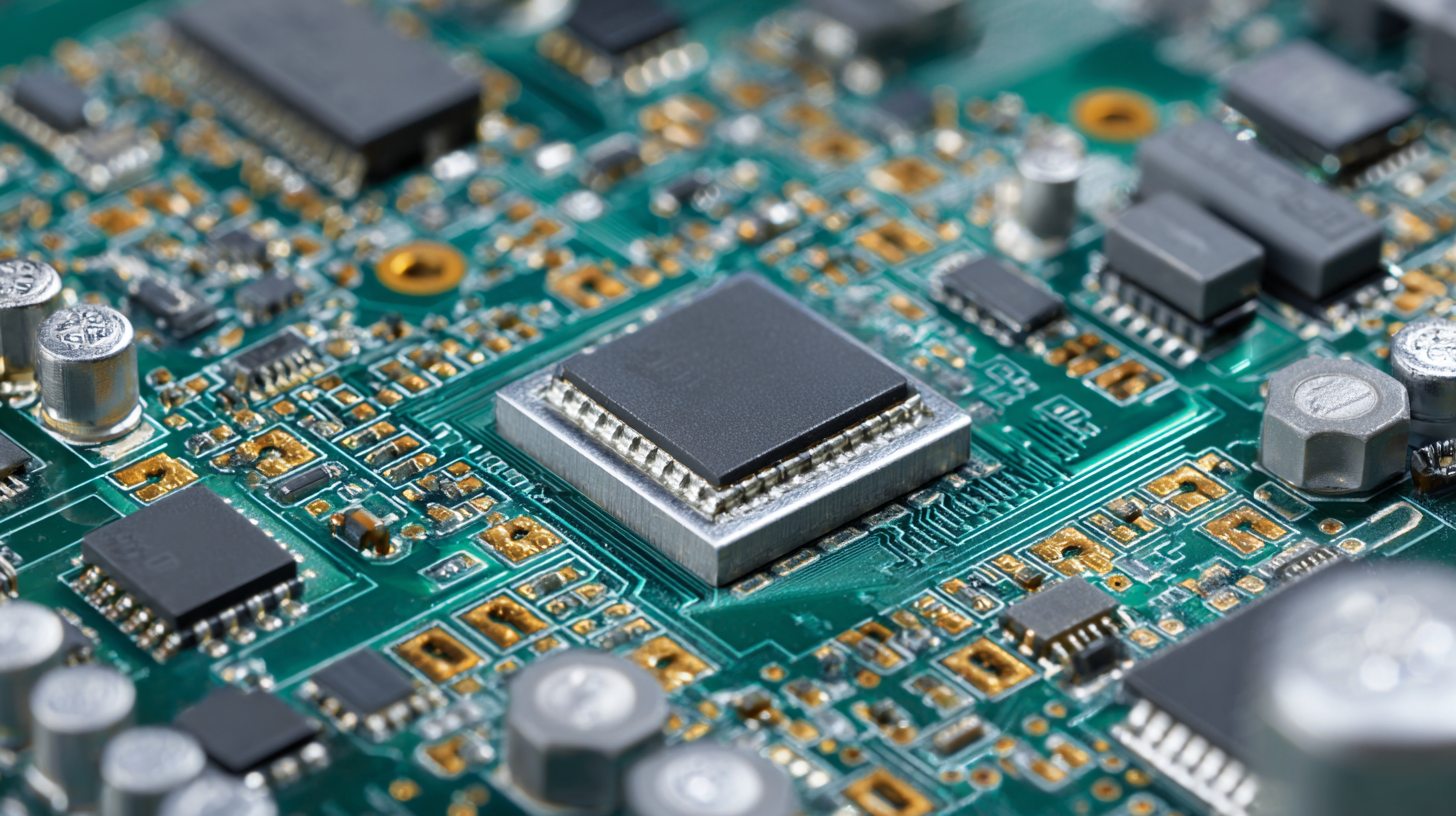

In the rapidly evolving landscape of electronics manufacturing, identifying top suppliers for PCB direct services has become paramount for companies aiming to remain competitive. According to a recent report from Technavio, the global PCB market is expected to reach $85 billion by 2025, driven by the increasing demand for advanced electronic systems in industries such as automotive, telecommunications, and healthcare. With this growth, the need for high-quality PCB direct manufacturing services is critical, as it directly impacts product reliability and performance. Furthermore, a study by MarketsandMarkets indicates that 70% of manufacturers consider supplier quality as a key factor in their procurement decisions. Thus, understanding how to effectively identify and partner with premier suppliers in this domain is essential for achieving operational excellence and innovation in product development.

Choosing the right PCB manufacturer is crucial for ensuring high-quality products that meet specific requirements. A reliable manufacturer not only understands the technical aspects of PCB fabrication but also prioritizes customer service and communication. This relationship can significantly reduce the likelihood of errors and delays, which are detrimental to any project timeline. When selecting a supplier, it’s essential to evaluate their experience, certifications, and ability to accommodate your unique specifications.

Furthermore, a top-tier PCB manufacturer invests in advanced technologies and adheres to strict quality control measures. This attention to detail can impact the durability and performance of the final product. Additionally, the right manufacturer should offer flexibility in production volumes, catering to both small prototypes and large-scale production. By focusing on these aspects, businesses can build a strong foundation for their projects, ensuring not just functionality but also long-term reliability in their PCB solutions.

Identifying top suppliers for PCB direct manufacturing services requires an understanding of key characteristics that define quality in this industry. According to the IPC A-600 standard, which outlines acceptability criteria for printed boards, a supplier's adherence to these quality benchmarks is crucial. A quality PCB manufacturer will consistently demonstrate low defect rates, typically less than 0.5%, as indicated by recent studies from the Electronics Manufacturing Services (EMS) industry. This reliability ensures that the products they deliver meet stringent performance and safety standards.

Another critical aspect is the manufacturer's technological capabilities. The demand for advanced PCBs is increasing, with a report by ResearchAndMarkets forecasting the PCB market to reach $85.6 billion by 2028, growing at a CAGR of 4.90%. Leading suppliers utilize state-of-the-art technology and processes, including automated assembly and robust testing methods, to ensure precision and quality. Furthermore, factors such as certifications (ISO 9001, ISO 13485) and the ability to offer quick turnaround times without compromising quality are essential indicators of a manufacturer's capability to meet the diverse needs of clients, ranging from prototyping to mass production.

When evaluating supplier capabilities for different PCB product types, it’s essential to identify specific criteria that align with your project's unique requirements. First, consider the supplier's manufacturing technology. Different PCB types, such as rigid, flexible, and rigid-flex, require specialized processes and equipment. Assess whether the supplier has invested in advanced machinery and technology that can meet your design specifications and volume requirements. This ensures that they can produce high-quality boards with precision and reliability.

Next, examine the supplier's experience and expertise in handling various materials and finishes. Different PCB applications may utilize diverse substrates such as FR-4, polyimide, or metal-core materials. A reputable supplier should possess not only the capability to work with these materials but also the expertise to provide insights on material selection and performance optimization. Furthermore, consider their ability to adhere to industry standards and certifications, which will indicate their commitment to quality and reliability in providing PCB direct manufacturing services.

Collaborating with top-notch PCB suppliers offers significant benefits that can elevate your manufacturing process. High-quality suppliers utilize advanced technology and rigorous quality control measures, ensuring that your printed circuit boards meet the highest standards. This level of quality can minimize defects and reduce production delays, ultimately leading to a more efficient assembly process.

When seeking the best PCB suppliers, consider these tips: First, evaluate their production capabilities. A reliable supplier should have a diverse range of manufacturing techniques and the ability to handle various order sizes. Second, check for certifications such as ISO or IPC standards; these accolades often indicate a supplier's commitment to quality. Lastly, look for suppliers with a strong track record of customer service. Responsive communication and support can make all the difference when addressing unforeseen challenges during production.

Investing time to find a reputable PCB supplier is invaluable. By partnering with experts who prioritize quality and reliability, you can ensure that your projects are completed on time and to specifications. This collaboration not only safeguards your reputation but also enhances overall project outcomes.

In 2025, the focus on assessing supplier reliability and quality assurance practices will be more critical than ever for businesses seeking a competitive edge, especially in PCB direct manufacturing services. One of the most effective approaches to ensure that suppliers meet high standards is through the implementation of Total Quality Management (TQM) principles. TQM emphasizes continuous improvement and fosters a culture of quality across all organizational levels, which not only enhances operational efficiency but also boosts customer satisfaction. By diligently evaluating supplier performance against TQM benchmarks, companies can identify reliable partners who prioritize quality and compliance.

To effectively monitor and evaluate suppliers, organizations should adopt systematic evaluation frameworks that consider both qualitative and quantitative metrics. Establishing clear communication channels and regularly conducting performance reviews can help assess whether suppliers maintain their commitment to quality and reliability. Additionally, organizations must remain vigilant against various supply chain threats, including cyber risks and environmental challenges, which can disrupt operations. By integrating TQM practices with robust supplier monitoring processes, businesses can mitigate these risks while enhancing overall operational performance and achieving sustainable growth in an increasingly complex market landscape.

| Supplier Location | Manufacturing Capability (Layers) | Average Lead Time (Days) | Quality Certification | Customer Satisfaction Rating |

|---|---|---|---|---|

| USA | 6 Layers | 15 Days | ISO 9001 | 4.7/5 |

| Germany | 8 Layers | 20 Days | IATF 16949 | 4.5/5 |

| China | 10 Layers | 25 Days | ISO 13485 | 4.3/5 |

| Taiwan | 12 Layers | 18 Days | UL Certified | 4.6/5 |

| South Korea | 4 Layers | 12 Days | ISO 9001 | 4.8/5 |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division