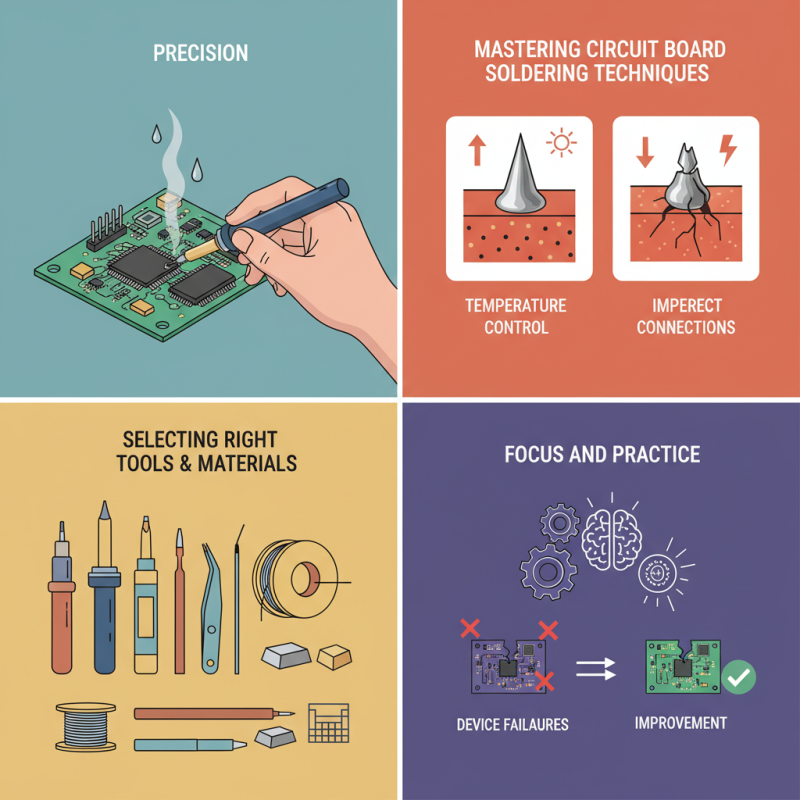

Mastering circuit board soldering techniques is crucial for anyone seeking to excel in electronics. According to renowned expert Dr. Linda Faulkner, "Precision in circuit board solder is a skill that comes with practice." The importance of mastering this craft cannot be overstated.

Circuit board soldering involves not just applying solder but also understanding the components involved. Beginners often struggle with techniques like temperature control and solder joint quality. It's not uncommon to find imperfect connections after several attempts. This can be frustrating. Yet, recognizing these challenges offers a path to improvement.

Effective soldering requires attention to detail. This involves selecting the right tools and materials. For instance, using the correct solder alloy can significantly impact the quality of your work. Many technicians overlook this aspect. The reality is that failing to master circuit board soldering can lead to device failures. Focus and practice are essential to overcome these hurdles.

Soldering is a fundamental skill in electronics. Understanding the basics helps in creating reliable connections on circuit boards. The soldering process involves melting a filler material, typically an alloy, to join electrical components. Proper technique is crucial for a good bond, as improper soldering can lead to failures.

According to industry reports, nearly 30% of assembly defects result from poor solder joints. This highlights the need for precision and care. Mastering temperature control is key. The ideal soldering temperature ranges from 350°C to 400°C. Going above this can damage components. Properly prepared surfaces lead to better adhesion, reducing possible repair needs later.

Practice is essential. Even experienced technicians make mistakes. Inconsistent pressure or movement can lead to cold solder joints. A clean workspace minimizes contamination, which often goes unnoticed but affects quality. Recognizing these challenges is critical. Continual improvement, patience, and reflection on past errors guide the path to mastery in soldering, ensuring reliable circuit board assemblies.

This bar chart illustrates the proficiency levels of different soldering techniques commonly used in circuit board assembly. Understanding these techniques can help enhance your skills in soldering.

Soldering is an essential skill for anyone working with circuit boards. To get started, you'll need several key tools. A good soldering iron is crucial. Look for one that heats quickly and maintains a stable temperature. Next, consider a soldering stand to hold your iron securely. This prevents burns and keeps your workspace organized.

You'll also need quality solder. A rosin-core solder is typically a good choice for electronics. It helps create better connections. Don't forget about a desoldering pump or braid. Mistakes happen, and these tools can save your work. Safety goggles are important too. They protect your eyes from accidental splashes of molten solder.

Maintaining your tools is important. Clean the soldering tip regularly to prevent oxidation. A dirty tip can lead to messy joints and frustration. If you're struggling, take a break. Sometimes, stepping back helps you see what went wrong. Soldering can be challenging, but with practice and the right tools, you can improve your technique.

Learning to solder circuit boards can be a rewarding skill. This guide will provide essential techniques for beginners. Start by gathering your tools: a soldering iron, solder, wire cutters, and safety goggles. Always work in a well-ventilated area.

Before soldering, practice holding the soldering iron. It should feel comfortable, but be mindful of the heat. A steady hand is crucial. Apply just enough solder to create a good joint, avoiding excess. Too much solder can lead to shorts and messy connections.

Tips: Keep your soldering iron clean. A dirty tip can affect heat transfer. Use a damp sponge to wipe it regularly. Don’t rush the process; patience is key. Mistakes will happen. If a connection fails, reheat and adjust. Learning from errors builds skill over time. Soldering requires practice. Every joint is a chance to improve. Focus on accuracy and take breaks when needed.

Soldering is a critical skill in circuit board assembly. Yet, many beginners make common mistakes that undermine their efforts. Poor cleaning of the circuit board is one of these major pitfalls. Residues can hinder solder adhesion. A study by the IPC found that nearly 30% of soldering failures result from inadequate surface preparation.

Another frequent mistake is overheating components. Excessive heat can damage sensitive parts, leading to malfunction. It is essential to control your soldering iron's temperature. Keep it within an optimal range—typically between 350°F to 400°F. Remember, a steady hand is crucial. A shaky hand can result in cold joints, which are weak and unreliable.

Additionally, ignoring proper soldering techniques can lead to significant issues. For instance, applying too much solder creates bridges between connections. This can cause short circuits. A well-executed joint should be shiny and smooth. It’s essential to inspect each joint carefully. Ensure they meet quality standards. Reflect on your process after each project to identify areas for improvement.

Mastering advanced soldering techniques is essential for experienced practitioners seeking precision and efficiency. One key skill is controlling the temperature of the soldering iron. Too high can damage components; too low may lead to cold joints. Each type of soldering requires a specific temperature range. Understanding this can greatly enhance the quality of your work.

Another crucial technique is proper flux application. Flux not only helps solder flow but also reduces oxidation. Applying the right amount can improve joints significantly. However, overusing flux can lead to messy boards. It takes practice to find the optimal balance. Occasionally, you may find solder pooling in unwanted areas. Reviewing these mistakes helps refine your technique.

Lastly, consider the impact of your workspace. A cluttered area can lead to accidents and mistakes. Having organized tools and materials is essential for focus. Yet, many practitioners often overlook this aspect. Regularly assessing your setup can boost productivity and lead to better outcomes. Remember, every soldering project teaches us something new. Embrace the imperfections and learn continuously.

| Technique | Description | Recommended Tools | Skill Level |

|---|---|---|---|

| Through-Hole Soldering | Inserting components through holes in the PCB and soldering them from the other side. | Soldering Iron, Solder, Flux | Beginner |

| Surface Mount Soldering | Attaching components directly onto the surface of the PCB. | Hot Air Rework Station, Solder Paste, Stencil | Intermediate |

| Lead-Free Soldering | Using alloys that do not contain lead for environmental compliance. | Lead-Free Solder, Soldering Iron | Intermediate |

| Reflow Soldering | Using a reflow oven to melt solder paste and attach components. | Reflow Oven, Solder Paste | Advanced |

| Wave Soldering | Immersing the PCB into a wave of molten solder. | Wave Soldering Machine | Advanced |

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division