In today's rapidly advancing manufacturing landscape, the importance of reliable after-sales support and maintenance for laser machines cannot be overstated. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 5.53 billion by 2025, growing at a CAGR of 5.8%. As businesses increasingly invest in laser technology to enhance precision and efficiency, comprehensive support systems become critical to maximize these investments. Implementing effective maintenance practices not only prolongs the lifespan of laser machines but also ensures optimal performance, reducing downtime and operational costs. This blog will delve into industry production standards and provide actionable tips on maintaining laser machines, empowering manufacturers to achieve peak productivity and profitability.

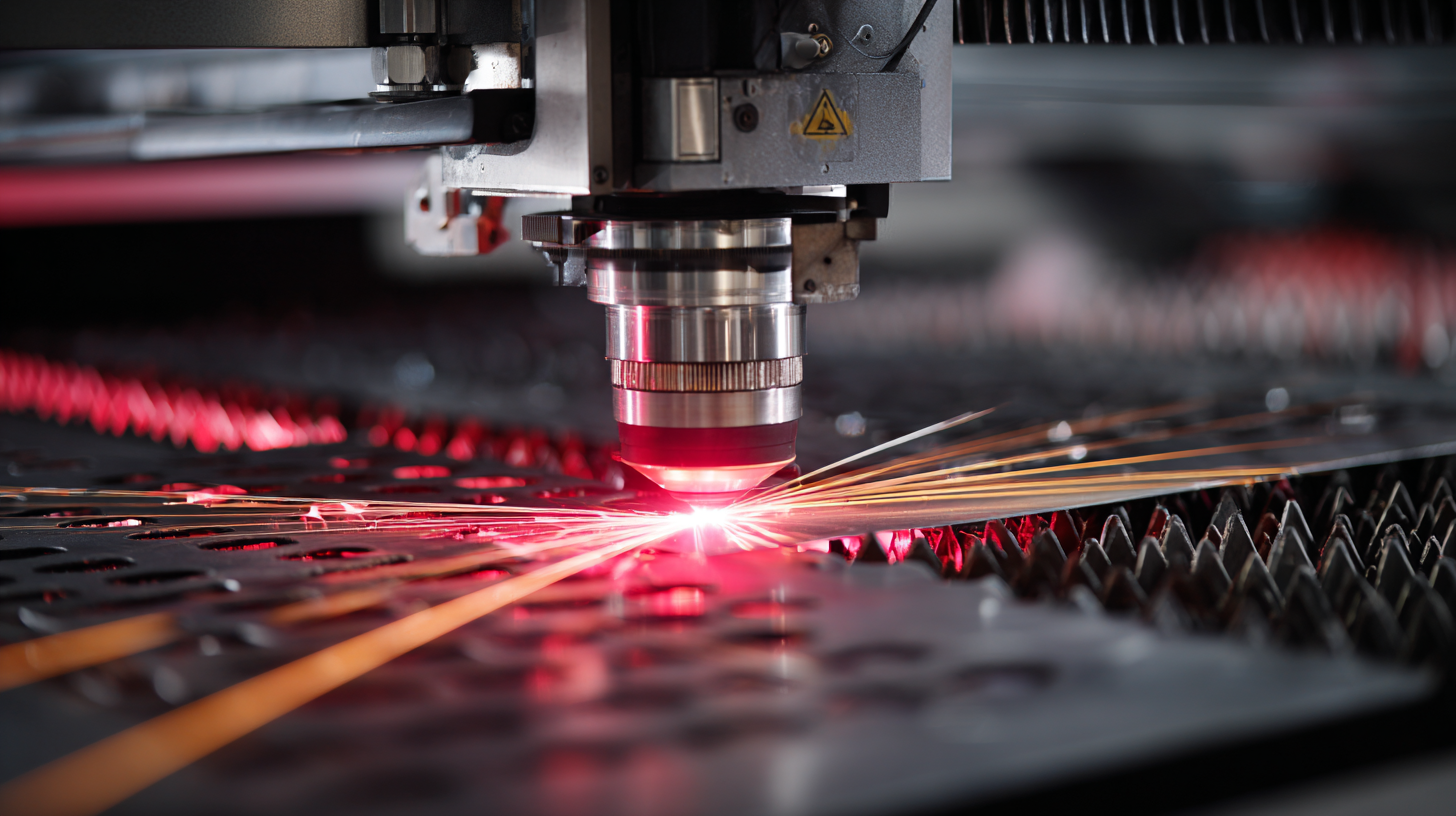

When investing in laser machines, understanding industry standards is crucial to ensuring optimal performance and safety in operations. The recent advancements in hand-held laser welding technology demonstrate the importance of adhering to these standards. Operators are now equipped with safety gear, including specialized helmets with laser-safe lenses, to mitigate risks associated with high-intensity laser operations. This highlights the industry's commitment to safeguarding workers while enhancing efficiency in metal fabrication.

Moreover, as the landscape of manufacturing evolves, including developments in metal additive manufacturing, it's essential to keep abreast of best practices in maintenance and after-sales support for laser machines. Proper upkeep not only extends the lifespan of the equipment but also ensures that it operates within the set industry standards. Adhering to these guidelines promotes not just operational safety but also increases productivity, allowing businesses to fully maximize their investment in laser technologies.

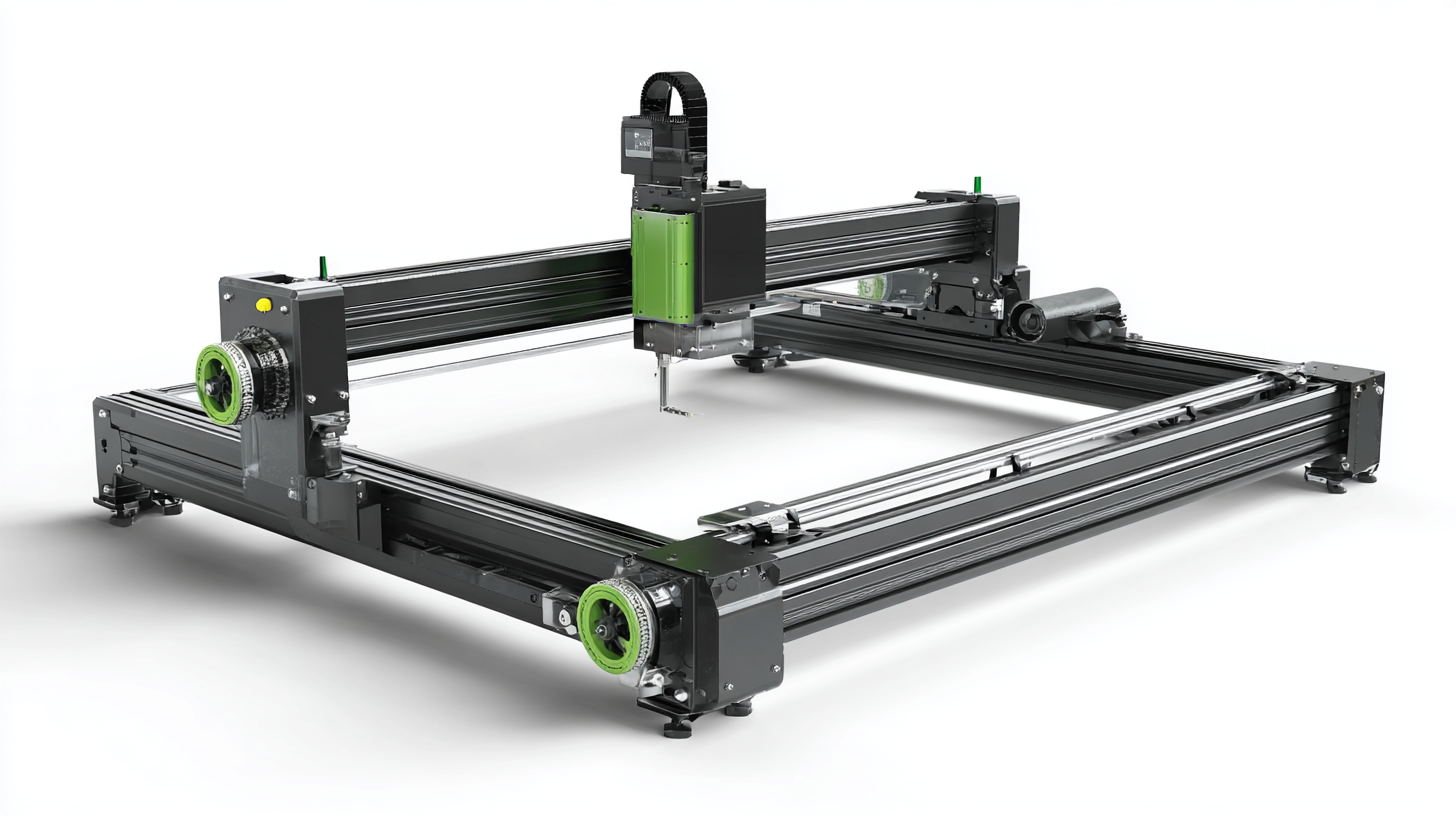

When it comes to maximizing your laser machine’s performance, regular maintenance is crucial. Adhering to essential maintenance tips not only prolongs the lifespan of your equipment but also enhances its efficiency. According to industry reports, machines that receive routine servicing can experience a lifespan increase of up to 30%, significantly reducing the need for early replacements. Furthermore, preventative maintenance can help pinpoint issues before they escalate, ensuring that your investments remain intact and operational.

Proper maintenance techniques include routine inspections, consistent cleaning, and lubrication of essential machine components. In the laser cutting industry, it’s critical to maintain optics and cooling systems to optimize cutting quality across different materials, whether it’s thick plate or intricate tubes. Studies have shown that well-maintained laser machines can maintain their cutting precision and speed even after prolonged use, allowing companies to take on a wider array of projects without sacrificing quality. Remember, while maintenance is key, understanding when to replace parts rather than repair is equally essential to keep your production running smoothly.

When considering the purchase of a laser machine, one pivotal aspect that often gets overlooked is the importance of robust after-sales support. Choosing the right after-sales services for your laser equipment can significantly influence your operational efficiency and longevity of the machine. A high-quality support system encompasses not just maintenance and repairs, but also training and readily available customer service. This holistic approach ensures that you can maximize productivity and minimize downtime, which is crucial for maintaining your competitive edge in the market.

The laser equipment market is expected to grow significantly, with forecasts indicating a robust expansion leading up to 2032. This growth necessitates that buyers prioritize after-sales support when selecting their equipment. Companies offering comprehensive maintenance plans and responsive customer service are likely to see increased loyalty from clients seeking reliability in their operations. By evaluating potential partners not just on price, but on the depth of their after-sales support, businesses can safeguard their investments and ensure sustainable growth in an increasingly competitive landscape.

When operating laser machines, users often encounter common issues that can disrupt workflow and impact overall productivity. One frequent problem is misalignment of the laser beam, which can result in uneven cuts or engravings. To troubleshoot this, make sure that the mirrors are properly adjusted and that the laser head is securely in place. It can also be beneficial to regularly clean the lenses and mirrors, as dust accumulation can affect performance.

Another prevalent issue is overheating, particularly in machines that running continuously or under heavy load. To prevent overheating, ensure that the cooling system is functioning correctly and that there’s adequate ventilation. If overheating occurs, allow the machine to cool down and inspect the cooling fans for blockages or malfunctions. Regular maintenance checks, such as replacing worn-out parts and keeping software updated, can greatly reduce the likelihood of these problems, ensuring optimal operation and longevity of your laser machine.

| Issue | Symptoms | Troubleshooting Steps | Maintenance Tips |

|---|---|---|---|

| Beam Misalignment | Uneven cuts, excessive smoke | Check mirrors and lens alignment | Regularly clean mirrors and lenses |

| Overheating | Machine shuts down, burning smell | Check cooling system and airflow | Ensure proper ventilation and cooling check |

| Software Issues | Errors during operation, program crashes | Update software, check for compatibility | Regularly back up settings and files |

| Inconsistent Cutting Depth | Variability in cut quality | Check material setup and power settings | Calibrate machine after changing materials |

| Lens Damage | Poor engraving, uneven surfaces | Inspect for scratches or dirt; replace if needed | Always clean with appropriate lens cleaner |

When it comes to operating laser machines, ensuring efficiency is key to maximizing performance and achieving optimal results. One of the best practices is to maintain a clean workspace. Dust and debris can interfere with the laser's functionality, leading to subpar results or even damage. Regularly cleaning the machine and keeping the surrounding area organized can significantly improve performance and extend the life of the equipment.

Another essential tip is to familiarize yourself with the manufacturer's guidelines for operation. Understanding recommended settings for different materials can enhance the quality of cuts and engravings. Additionally, taking the time to calibrate the machine before each job can prevent errors and ensure consistency, ultimately saving time and material costs. This attention to detail lays the foundation for effective laser machine care.

Lastly, keep an eye on the machine’s components for signs of wear and tear. Regularly check lenses, mirrors, and belts; replace or clean them as necessary to maintain peak performance. Implementing a routine maintenance schedule based on usage can prevent unexpected breakdowns and reduce downtime, allowing for a more efficient workflow.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division