The laser manufacturing process has revolutionized various industries, including automotive, aerospace, and electronics. According to a report by MarketsandMarkets, the global laser market is expected to reach $11.6 billion by 2026, showcasing rapid growth and innovation. This surge highlights the importance of understanding the intricacies of laser technology.

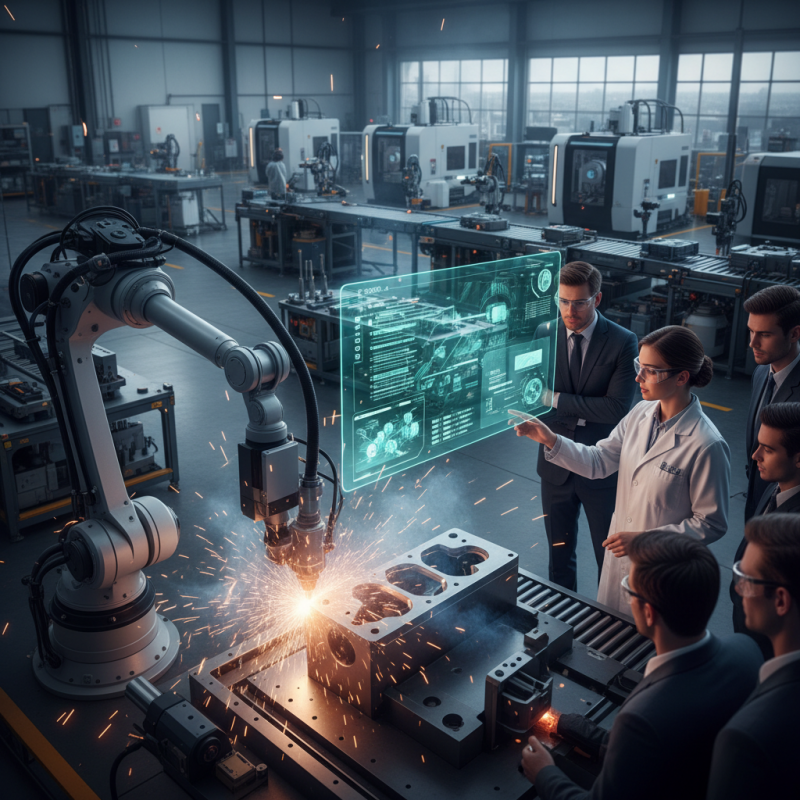

Dr. Emily Tran, a renowned expert in laser applications, emphasizes, "Mastering the laser manufacturing process requires a deep understanding of both the technology and its applications." This statement underscores the need for precise knowledge to harness the full potential of lasers. Many companies struggle with inefficiencies and waste due to inadequate understanding, leading to missed opportunities.

As industries continue to adapt and integrate advanced technologies, the laser manufacturing process will be at the forefront. However, without proper understanding, the risk of setbacks increases. Recognizing the various factors—such as material selection and process parameters—can significantly improve outcomes. Engaging with industry experts and real-world examples can bridge this knowledge gap.

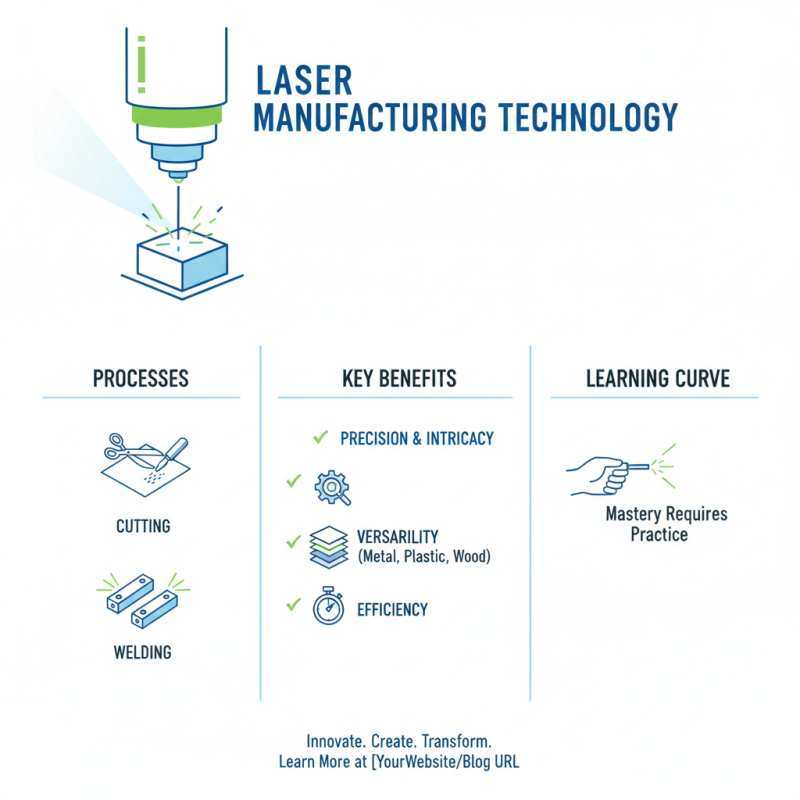

Laser manufacturing technology has revolutionized various industries. It uses focused light beams to cut, engrave, and weld materials. This precision process allows designers to create intricate shapes with ease. Metal, plastic, and wood are commonly processed with lasers. The versatility of this technology is remarkable. However, achieving the perfect cut or engraving requires practice.

Understanding laser parameters is critical. Factors like power, speed, and frequency play a significant role. Improper settings can lead to burnt edges or incomplete cuts. Feedback from operators is essential. They often need to adjust settings based on material and desired outcome. There's a learning curve involved. Mistakes happen, and each failure brings valuable lessons.

Laser machines can be complex. Familiarizing oneself with software and equipment is not always straightforward. Some users feel overwhelmed at first. Experimenting with small projects can help build confidence. Failing during this phase is common, but it’s part of growth. Continuous learning is crucial in mastering this technology. Each attempt brings you one step closer to perfection.

Laser cutting and engraving are fascinating processes that have transformed manufacturing. Understanding the key principles behind these methods is crucial for designers and engineers. Both processes use concentrated beams of light to cut or engrave materials. This energy is precise and efficient. It allows intricate designs that traditional methods struggle to achieve.

The high-temperature laser vaporizes materials, creating clean cuts. This is particularly useful for materials like wood, acrylic, and metals. However, some users face challenges, such as edge quality. Not every cut is perfect. Adjusting the laser settings can be tricky. The speed, power, and focus of the laser need to be balanced. Even slight variations can lead to different outcomes.

Engraving, on the other hand, involves etching designs onto materials. The laser removes small amounts of material, creating textured effects. Engraving depth can vary, impacting the final appearance. It’s essential to select the right materials for the desired effect. Sometimes, experimentation is necessary. Some designs can appear poorly executed on the first try. Refinement is part of the learning curve in mastering these techniques.

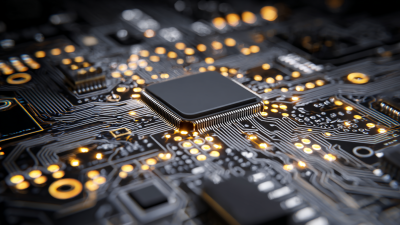

Laser manufacturing has gained traction in various industries due to its precision and versatility. Commonly used materials in this process include metals, plastics, and ceramics. Metals like steel and aluminum are favored for their strength and durability. According to a recent industry report, around 50% of laser cutting applications utilize these materials.

Plastics are another significant category. They are often used in applications needing lightweight and corrosion resistance. Acrylic and polycarbonate are readily selected because of their excellent optical properties. A study revealed that laser cutting of plastics increased by 30% in the last two years. This growth emphasizes the rising demand for lightweight solutions in sectors such as automotive and aerospace.

Ceramics are also becoming popular, especially in advanced manufacturing. Their heat resistance makes them valuable for electronics and medical devices. However, working with ceramics can be challenging. They are brittle and prone to cracking. This requires careful consideration during the design phase. Balancing material choice with application requirements is crucial. It's evident that while laser manufacturing is transformative, selecting the right material remains a complex task.

Laser manufacturing processes offer various advantages. They provide precise cutting and engraving capabilities. This accuracy results in minimal material waste. With faster turnaround times, efficiency is significantly improved. Additionally, laser technology can handle complex shapes that traditional methods may struggle with. This flexibility is appealing in various industries.

However, there are limitations to consider. The initial cost of laser equipment can be high. Not all materials are suitable for laser cutting or engraving. Some thicker materials may not achieve the desired precision. Safety also poses concerns; powerful lasers require strict handling protocols. Moreover, the learning curve can be steep for new operators. These challenges suggest that while lasers are powerful tools, they come with their own set of hurdles.

| Aspect | Description | Advantages | Limitations |

|---|---|---|---|

| Laser Cutting | A process that uses a laser beam to cut materials. | High precision, minimal waste, and ability to cut intricate designs. | Limited thickness of materials, slower for thicker materials. |

| Laser Engraving | Using laser technology to engrave designs on surfaces. | High detail accuracy and customization potential. | May require post-processing for certain materials. |

| Laser Welding | Joins materials by melting them with a laser beam. | Strong welds with minimal heat-affected zone. | Initial setup cost can be high; requires skilled operators. |

| Laser Marking | Creating permanent marks on a surface using a laser. | High speed and efficiency, ideal for production lines. | Limited to surface applications and may not be applicable on all materials. |

| Material Compatibility | Different materials react uniquely to laser applications. | Versatile applications across metals, plastics, and wood. | Not all materials are easily processed; some may require specific settings. |

In laser manufacturing, safety is paramount. Operators must wear appropriate protective gear, including goggles to shield their eyes from intense light. The workspace should be well-ventilated to disperse harmful fumes. Not every facility has adequate safety measures, which can lead to accidents.

Lasers emit high levels of energy, and this poses risks. Equipment malfunction could cause injuries. Regular maintenance is essential to ensure tools are in good condition. Any signs of wear should not be ignored. Training personnel on emergency procedures is also crucial. It allows everyone to respond quickly in case of an incident.

Personal safety should not be taken lightly. Awareness and adherence to safety protocols protect not just the operator but also bystanders. Reflecting on past incidents can provide valuable lessons. A culture of safety encourages open discussions about potential hazards. Creating an environment where questions are welcomed is vital for improvement.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division