As the demand for innovative building materials continues to rise, aluminum composite panel manufacturers are at the forefront of the industry. According to John Smith, a leading expert in architectural materials, "The future of construction rests on versatile solutions like aluminum composite panels." His words highlight the growing significance of these materials in modern architecture.

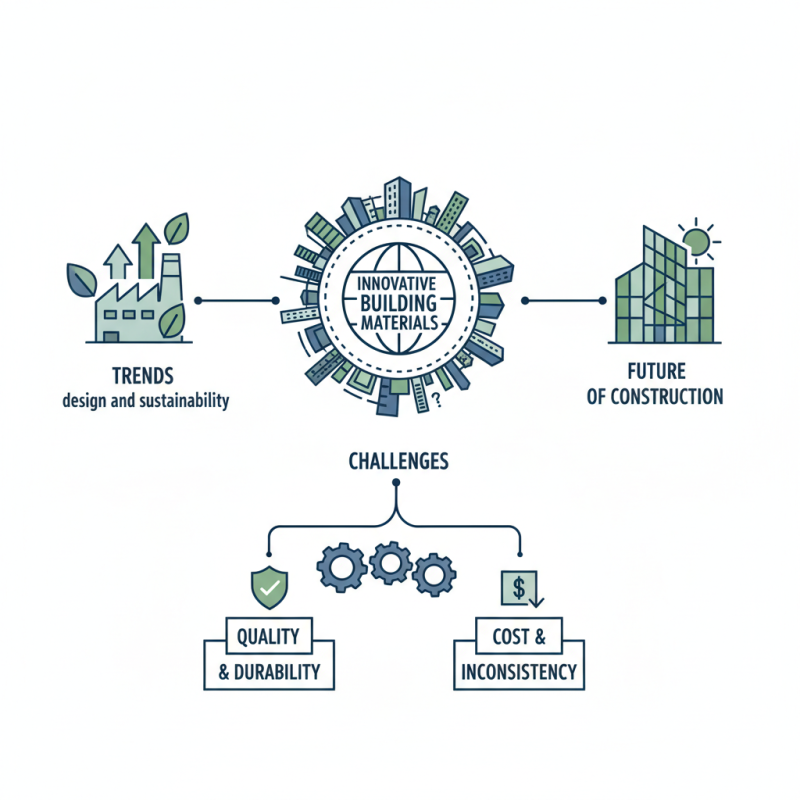

In 2026, understanding the landscape of aluminum composite panel manufacturers will be crucial for architects and builders. The industry is evolving rapidly, influenced by trends in design and sustainability. Many companies are striving to produce panels that not only meet aesthetic needs but also environmental standards. However, not all manufacturers prioritize quality and sustainability equally.

Some manufacturers still lag in adapting to new technologies. This inconsistency can lead to confusion in the market. Architects must navigate through various options, weighing durability against cost. The journey towards finding the right supplier may not always be smooth. Yet, it is essential for achieving long-lasting results in construction projects.

The aluminum composite panel (ACP) market is evolving rapidly. By 2026, it is projected to reach a value of approximately $8 billion, driven by its popularity in construction and design. Trends indicate that ACPs are favored for their durability, aesthetics, and ease of installation. In regions like Asia Pacific, demand has surged, with a growth rate exceeding 5% annually.

However, challenges persist in the industry. Environmental concerns about production processes are growing. Demands for sustainable materials are increasing. Many manufacturers are exploring alternative solutions. This shift may lead to higher production costs, impacting prices. Quality control remains another critical issue, as inconsistencies can undermine market confidence. Reports show that over 15% of panels fail to meet industry standards.

As manufacturers adapt to these changes, innovation is key. New technologies are enhancing panel performance and reducing costs. However, the reliance on automation could lead to job losses. The balance between efficiency and workforce sustainability is a crucial consideration for the future. Understanding these dynamics will be essential for stakeholders navigating the ACP landscape by 2026.

The demand for aluminum composite panels (ACP) is seeing significant shifts in 2026. Sustainability is a major trend. Many businesses now prioritize eco-friendly materials. Consumers want products that are both stylish and environmentally friendly. This growing awareness drives manufacturers to innovate.

Design versatility plays a crucial role. Architects and builders seek customizable options, which allows for unique aesthetics. Advanced manufacturing technologies are pushing boundaries. Panels are becoming lighter, stronger, and available in a wider range of colors and finishes. These advancements enhance their appeal in the construction industry.

Tips: Explore local suppliers for unique designs. Check for certifications indicating eco-friendly practices. Remember, aesthetics matter but don't overlook durability. Make informed choices while combining style with sustainability. Embrace new technologies, but keep an eye on practicality. Each decision shapes the future of construction.

The landscape for aluminum composite panel manufacturers is evolving rapidly. In 2026, several key competitive factors will influence their success. Quality control remains paramount. Manufacturers need to maintain high standards in material sourcing and production processes. This can be challenging. Mistakes can lead to defects that are costly.

Innovation will play a critical role as well. Companies must develop new designs and applications for aluminum composite panels. Staying ahead of design trends is vital. However, the process of innovation can sometimes be inconsistent. It’s an area needing constant focus.

Sustainability concerns are growing. Manufacturers are under pressure to use eco-friendly materials and practices. This shift may require significant changes in operations. Many companies might struggle with this transition. Balancing sustainability with cost-effectiveness is a complex task. It's a challenge that demands reflection and adaptation.

| Manufacturer | Annual Production Capacity (Units) | Market Share (%) | Key Features | Price Range (per sqm) |

|---|---|---|---|---|

| Manufacturer A | 1,000,000 | 15% | Fire-resistant, Eco-friendly coating | $30 - $50 |

| Manufacturer B | 800,000 | 12% | Lightweight, High durability | $25 - $45 |

| Manufacturer C | 1,200,000 | 20% | Color fastness, Customized designs | $35 - $55 |

| Manufacturer D | 900,000 | 10% | Impact resistance, Vibrant colors | $28 - $48 |

| Manufacturer E | 1,500,000 | 18% | Easy installation, Weather resistant | $32 - $52 |

Innovations in aluminum composite panel production are reshaping the industry. New technologies focus on improving efficiency and sustainability. Advanced coating processes are now popular, enhancing both and aesthetic appeal. Also, novel bonding techniques reduce environmental impact. These changes are crucial as the industry faces scrutiny over ecological footprints.

Notably, automation plays a key role. It streamlines production lines, reducing human error. However, reliance on technology raises questions: Can machines replace human creativity? Some producers struggle to find the right balance. Training workers to utilize this technology is essential; without skilled labor, advancements may stall.

Sustainability is another area of focus. Manufacturers are adopting eco-friendly materials. These alternatives often come with challenges. Finding the right blend of performance and sustainability is complex. The path to greener production is not always straightforward. There are trade-offs to consider, especially in cost and availability. Navigating this landscape requires careful thought and ongoing assessment.

Sustainability practices are critical for aluminum composite panel manufacturers. These companies are exploring innovative methods to reduce their environmental impact. Many are investing in recycling initiatives to minimize waste. Recycled aluminum can decrease the carbon footprint significantly. Some producers are trying to source raw materials from responsibly managed suppliers.

However, the journey toward complete sustainability is complex. Not all manufacturers follow the same path. Transparency in these initiatives can be lacking. Customers often find it challenging to identify which companies truly commit to sustainability. There is a noticeable gap between promises and actual practices.

Manufacturers face the challenge of balancing cost and eco-friendliness. Sustainable options can sometimes lead to higher production costs. This puts pressure on companies to deliver affordable products. Finding an equilibrium between quality, cost, and sustainability remains a point of reflection. Effective communication about sustainability efforts is essential. Without it, trust can falter.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division