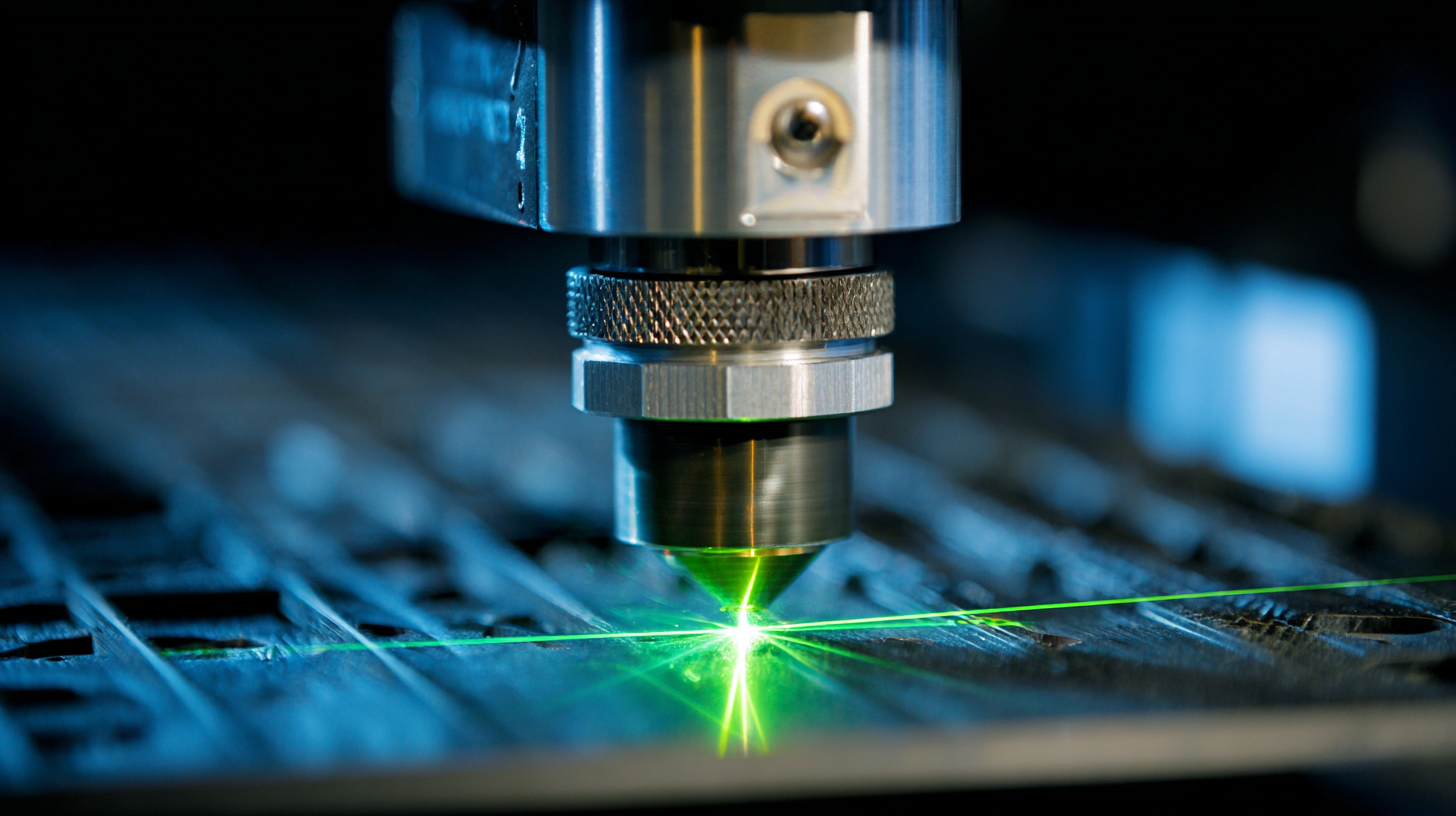

In today's rapidly evolving manufacturing landscape, the importance of adhering to industry standards cannot be overstated, particularly in the realm of the laser manufacturing process. As businesses strive to enhance efficiency and product quality, understanding the intricate web of regulations surrounding imports and exports becomes crucial. This blog delves into the significance of selecting the best laser manufacturing process, highlighting five key reasons that underscore not only operational excellence but also compliance with global industry standards. By exploring the alignment of cutting-edge technology with rigorous quality assurance measures, we aim to shed light on how choosing the right process can significantly impact a company's market presence and credibility, ultimately leading to sustained success in a competitive environment. Join us as we navigate the complexities of laser manufacturing and its integral role in meeting the demands of modern industries.

In the rapidly evolving field of laser manufacturing, understanding industry standards is crucial for ensuring quality and consistency. These standards provide a framework that helps manufacturers optimize processes, reduce waste, and enhance product reliability. By adhering to established protocols, businesses can navigate the complexities of the laser manufacturing landscape while contributing to a more sustainable future.

When considering the adoption of laser manufacturing processes, it is essential to evaluate their fit within the future Circular Economy paradigm. For instance, the use of Wire DED technology with E-beam sources presents both opportunities and challenges. This innovative approach allows for the precise deposition of material, resulting in reduced material waste and energy consumption. However, manufacturers must remain vigilant about the technical hurdles and potential scalability issues that accompany new technologies.

Tips:

Choosing the right laser manufacturing partner is crucial for ensuring high-quality outcomes in any project. When evaluating potential partners, it’s essential to consider their expertise in specific laser technologies and their track record in your industry. A partner with a deep understanding of your sector can tailor solutions that meet your unique requirements, ultimately enhancing efficiency and product quality.

Tip: Always ask for case studies or references to assess the partner's capabilities and experience. This will give you insights into their problem-solving approach and the results they’ve achieved for similar projects.

Another factor to consider is the technology and equipment that the manufacturer uses. Cutting-edge laser technology can significantly impact production speed and precision. A partner who invests in modern equipment demonstrates a commitment to quality and innovation, which can translate into better service for your project.

Tip: Inquire about the maintenance protocols for their machinery to ensure consistent performance and reliability in their production processes. This information will help you gauge their dedication to maintaining high manufacturing standards.

Adhering to industry standards in laser manufacturing can significantly enhance production quality and drive operational efficiency. According to a report by the International Organization for Standardization (ISO), companies that comply with established quality management systems experience a 20% increase in customer satisfaction. This underscores the importance of consistently meeting high standards, which not only improves product reliability but also fosters brand loyalty among consumers.

Moreover, essential industries such as automotive and aerospace heavily rely on adherence to industry standards to mitigate risks associated with non-compliance. The National Institute of Standards and Technology (NIST) reports that about 80% of manufacturers implementing industry standards witness fewer defects and rework costs, ultimately resulting in a 10-15% increase in overall productivity. By adopting these recognized manufacturing processes, companies can not only ensure superior quality but also position themselves favorably against competitors in a rapidly evolving market.

The adoption of advanced laser manufacturing processes is on the rise, as industries strive for greater efficiency and precision. According to a report by MarketsandMarkets, the global laser cutting market is expected to grow from $3.6 billion in 2020 to $5.9 billion by 2025, underscoring the significance of these technologies in meeting modern production demands. Efficiency metrics, such as cutting speed and energy consumption, are critical in evaluating laser systems. For instance, fiber lasers typically operate at speeds of 20 to 100 inches per minute, significantly outperforming traditional cutting methods.

Tip: When selecting a laser manufacturing process, consider both the initial investment and long-term efficiency. Operations that integrate automated systems achieve up to 50% more output than manual processes.

Precision is non-negotiable in laser manufacturing. According to a study by the International Journal of Advanced Manufacturing Technology, laser systems can achieve tolerances of up to 0.01 millimeters, making them ideal for intricate designs in industries like aerospace and medical devices.

Tip: Regular maintenance and calibration of laser equipment can enhance precision and reduce downtime. Implementing predictive maintenance strategies can lead to a 25% increase in operational efficiency.

The non-metal laser engraving machine market is poised for significant growth, projected to reach a value of $359.1 million in 2024 and escalate to $575.9 million by 2032, demonstrating an annual growth rate of 6.1%. This upward trend highlights the increasing adoption of laser technology across various industries, fueled by the demand for precision and efficiency in manufacturing processes. As we look towards the future of laser manufacturing, it is essential to stay informed about emerging trends and best practices that can drive innovation.

One critical aspect to consider is the impact of artificial intelligence on laser technology applications. Experts predict that AI will enhance laser manufacturing processes by integrating advanced analytics and automation, optimizing production efficiency while minimizing waste. Companies that leverage AI alongside traditional laser solutions are likely to gain a competitive edge in the market.

Tips for staying ahead in the laser manufacturing sector include investing in robust training programs for staff to ensure they are adept with the latest technology advancements, and continuously monitoring market trends to adapt business strategies accordingly. Engaging with industry conferences and forums can also provide valuable insights and networking opportunities, paving the way for collaborative innovations in laser solutions.

This chart illustrates the growing importance of various factors in choosing the best laser manufacturing process over the past few years. The data highlights key areas such as Efficiency, Cost, Precision, Sustainability, and Innovation.

„Thanks to the LUVIR technology, the solder resist process could be switched directly from the previously used mask exposure to direct exposure. As an outstanding digital solution on the market, this technology has been able to demonstrate fast process times and superior quality on our certified conventional ink in production. This allowed us to fully digitize the solder mask process at low cost – without process or ink adjustments. An excellent benefit to our production in Rot am See.“

Ralf Göhringer (Head of Production WE Rot am See)

I would definitely recommend the Limata machine and team for a future company purchase

Michael Greenaway

Compunetics Inc.

“The Limata ldi has been amazing!! Best thing we did was buy this machine”

Richard Brady

GM

Circuitlabs

“Since 2019, we have been running the Limata X1000 LDI system (including LUVIR for solder mask imaging) in daily production as an addition to our current process with film. The machine was capable of properly exposing Taiyo PSR-4000 BN (DI) solder mask types on normal to high-copper boards using a new and unique direct imaging process. The machine operating interface is very user friendly which allowed for a quick technical training curve. The pre-registration processing reduced several seconds of production time at every print. Limata support and service staff is incomparable. They supported our team every step of the way at basically any time of the day or night, with literally, an immediate response time, customizing the software interface to best fit our Operations and needs.

We have exposed more than 8,000 prints since end of October, on various solder mask colors and some resist film panels. Limata, has proven to be very capable and innovative. They are a strong contender in the industry.

We have very much enjoyed this project, and working with the team!

Thank you Limata for the continued support and being a part of our growth.”

Bill Sezate

Vice President, GM

Summit Interconnect

As a replacement to our current contact exposure process with film, the LIMATA X2000 system including LUVIR-Technology was capable of properly exposing non-LDI solder mask types using a direct imaging process. The machine offers cutting edge software with a very intuitive operating interface which allowed for quick technician training curve. The dual drawer system combined with pre-registration processing reduced several seconds of production time at every machine cycle. Limata support and service staff is world class. They added software patches to keep production running at shortest possible response times, customized the software interface to best fit our in-house Operations system, and even wrote a step-by-step machine processing manual. As a result of the project, we have exposed more than 16,000 times on various product types and solder mask brands/colors. Limata, in a very short timeframe as a company, has definitely shown they are truly innovative and will be challenging the industry of direct imaging for the top spot.

Kevin Beattie

Process Engineer

TTM Technologies

Forest Grove Division